✓Concrete is a composite material composed of a mixture of fine and coarse aggregates bonded with biding material, which hardens over time. The binding material primarily includes fluid cement paste, lime putty, lime, etc.

✓ In other words, when water is added to a mixture of cement, and fine and coarse aggregates, a workable paste is formed, which hardens with time. Such paste is known as Concrete.

✓ The binding material, such as cement, reacts with the water and other constituents to form a hard matrix that binds the materials together into a durable stone-like material with many uses. Concrete is a type of construction material used all over the world. It is often said that the present age is a concrete age.

✓ Concrete is extensively used to construct columns, beams, foundations, slabs, and other load-bearing elements of buildings, roads, dams, bridges, etc.

✓ The growing popularity of Concrete in civil engineering works is due to its distinctive characteristics like strength, durability, low maintenance, energy efficiency, and sustainability.

✓ Similarly, the broad range of concrete applications has paved the way for developing various equipment, such as concrete mixers, for smoother construction operations. More specialized concrete-related products and services have also emerged.

✓ Among them are concrete mixer hire services. Equipment rental companies typically provide them, offering different sizes and types of equipment according to a project’s specific requirements. The rental period can vary, depending on the agreement between the renting party and the equipment provider.

✓ These tools are dedicated to specific functions. For example, concrete pumps help place Concrete into hard-to-reach areas or at significant heights. Concrete testing instruments are also now available to assess the properties and quality of concrete mixtures. These tools measure compressive strength, slump (consistency), air content, moisture, and curing conditions.

✓ Tools that remove air bubbles and consolidate freshly poured Concrete are called vibrators. They have internal vibrators (immersed in Concrete) and external vibrators (applied externally to the formwork).

✓ On the other hand, structures or molds contain and shape Concrete during the pouring and curing process. They can be made of wood, steel, aluminum, or plastic and come in various sizes and configurations. Steel bars or mesh reinforce concrete and enhance its strength. Chemical compounds are also available, added to concrete mixtures to modify their properties.

✓ The primary application areas of Concrete include the following:

b. Residential and Commercial Buildings

c. Roads and Driveways

d. Foundations

e. Culverts and Sewers

f. Fences

g. Concrete Bridges

h. Marine Constructions

1. Types of Concrete

✓ The classification of Concrete is done based on various factors such as types of material used in the preparation of Concrete, the density of Concrete, the nature of the stress conditions, etc. The different types of Concrete have been further discussed below:

a. Plain Concrete / Ordinary Concrete

✓ Plain Concrete is also commonly referred to as ordinary Concrete.

✓ It is one of the most extensively used Concrete worldwide.

✓ Plain Concrete constitutes cement, sand, and coarse aggregates mixed with a definite proportion of water.

✓ The proportion of the different constituents may vary depending upon the application of the Concrete. The most commonly adopted proportion of plain Concrete is 1:2:4.

✓ Plain Concrete is widely used to construct buildings, pavements, dams, and other structures where high tensile strength is generally not required.

Some of the essential properties of plain Concrete can be listed as follows:

a. The density of plain Concrete varies from 2200 kg/m³ to 2500 kg/m³.

b. The compressive strength of plain Concrete varies from 200 kg/cm² to 500 kg/cm².

c. The degree of durability of plain Concrete is satisfactory.

Some of the uses of Plain Concrete can be listed as follows:

a. It can be used as bed concrete below the wall footings, column footings, and walls below the beams.

b. It can be used as sill concrete to achieve an even and hard surface at the window and ventilator sills.

c. It can be used for coping works over the parapet and compound walls.

d. It can be used to construct buildings, retaining walls, and pavements that do not require high tensile strength.

e. It can be used for dam construction and lining storage tanks and reservoirs.

f. It can also be used for plinth protection works.

However, a significant limitation of Plain Concrete is that it is not suitable for constructing structures that are likely to be subjected to wind, seismic, etc.

b. Lightweight Concrete

✓ Lightweight Concrete can be defined as a type with a density of less than 1920kg/m³.

✓ Lightweight Concrete is also commonly referred to as cellular Concrete.

✓ This type of Concrete contains a mixture of lightweight coarse aggregates, fine aggregates, binding material, and water in a definite proportion.

✓ The lightweight aggregates commonly used include expanded shale, clay, and other similar materials that have been burned in a rotary kiln and thus have developed a porous structure.

✓ Blast furnace slag is sometimes used as aggregate for lightweight Concrete.

✓ Primarily, the density of the lightweight Concrete may vary between 1440kg/m³ to 1840kg/m³.

Some of the uses of lightweight Concrete can be listed as follows:

a. It is extensively used for screeds and thickening purposes such as roofs, floors, etc.

b. It can be used for the casting of structural steel to prevent it from fire hazards, corrosion, etc.

c. It can be used for heat insulation on roofs and insulating water pipes and walls.

d. It can be used to construct general partition and panel walls in the frame structures.

e. It can be used for the surface rendering of external walls in residential buildings.

f. The possibility of spalling is relatively lower in lightweight Concrete.

Some of the advantages of lightweight Concrete can be listed as follows:

a. The lightweight Concrete dramatically reduces the dead load and thus allows a longer span.

b. The decreased dead load also ensures lower haulage and handling costs; thus, a faster construction rate can be achieved.

c. Using lightweight Concrete in the construction of floors, partition walls, external cladding, and other structural members of the frame structures can offer greater flexibility in design and save the time and cost of construction.

d. Due to the low thermal conductivity of lightweight Concrete, it can be used for insulation works.

✓ However, a significant disadvantage of lightweight Concrete is that the depth within which corrosion can occur is nearly twice that of ordinary Concrete.

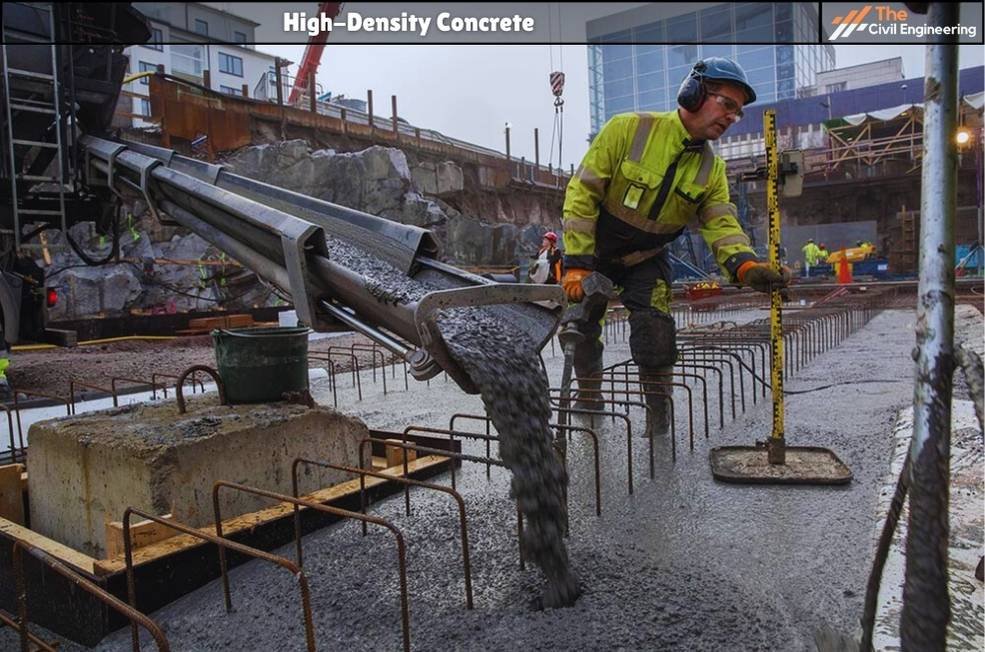

c. High-Density Concrete

✓ As the name implies, it has a relatively higher density than other types of Concrete.

✓ This type of Concrete is also commonly referred to as heavyweight Concrete.

✓ The high-density Concrete is manufactured from high-density crushed rocks and similar coarse aggregates such as barites, magnetites, etc.

✓ Mostly, the density of such concrete ranges from 3000 kg/m³ to 4000 kg/m³.

Some of the essential uses of high-density Concrete can be listed as follows:

a. It is extensively used in nuclear power plants and similar structures.

b. It is also used for high-density radiation shielding purposes.

Some of the advantages offered by high-density Concrete can be listed as follows:

a. It offers high gamma-ray and neutron attenuation.

b. This type of Concrete has good mechanical properties and is suitable for a wide range of structural constructions.

✓ However, the major disadvantage of high-density Concrete is that it has heavyweight, and thus, handling such Concrete may be troublesome.

d. Reinforced Concrete

✓ Reinforced Concrete is commonly called RCC, i.e., reinforced cement concrete.

✓ It is obtained from conventional cement concrete after the addition of reinforcement in it. The support includes steel bars, rods, and meshes.

✓ The primary objective of using reinforced Concrete is to ensure that the Concrete has considerable compressive as well as tensile strength.

✓ It is made such that the reinforcements withstand the tensile forces while the Concrete resists the compressive forces.

Some of the advantages of reinforced Concrete can be listed as follows:

a. It imparts high compressive and tensile strength.

b. It offers good durability with low maintenance costs.

c. It offers considerable resistance to fire hazards and weathering.

d. The construction using this type of Concrete requires a less skilled workforce.

Some of the disadvantages of reinforced Concrete can be listed as follows:

a. It does not have certainty of final strength, i.e., the absolute power of the reinforced Concrete depends upon mixing, casting, and curing of the Concrete.

b. This type of Concrete is prone to the development of shrinkage cracks.

c. The tensile strength of reinforced Concrete is only about one-tenth of the compressive strength.

e. Precast Concrete

✓Precast Concrete is a construction product produced by casting the Concrete in the steel or timber mold, which is then cured and transported to the site for assembly.

✓ This type of Concrete is used in beams, columns, panels, floors, tunnels, concrete lintels, staircase units, fences, precast poles, etc.

The major applications of precast Concrete can be listed as follows:

a. It is extensively used in structural components such as beams, columns, panel walls, floors, etc.

b. It is also used to make various prestressed precast building elements.

c. It is used for various utilities such as water tanks, drainage chambers, septic tanks, tunnels, etc.

d. It can be easily molded into any desired shape and thus is used in various architectural monuments, sculptures, etc.

✓ The primary disadvantage of precast Concrete is that it is cumbersome and large. Thus, the handling and assembling of the precast Concrete can pose significant difficulties.

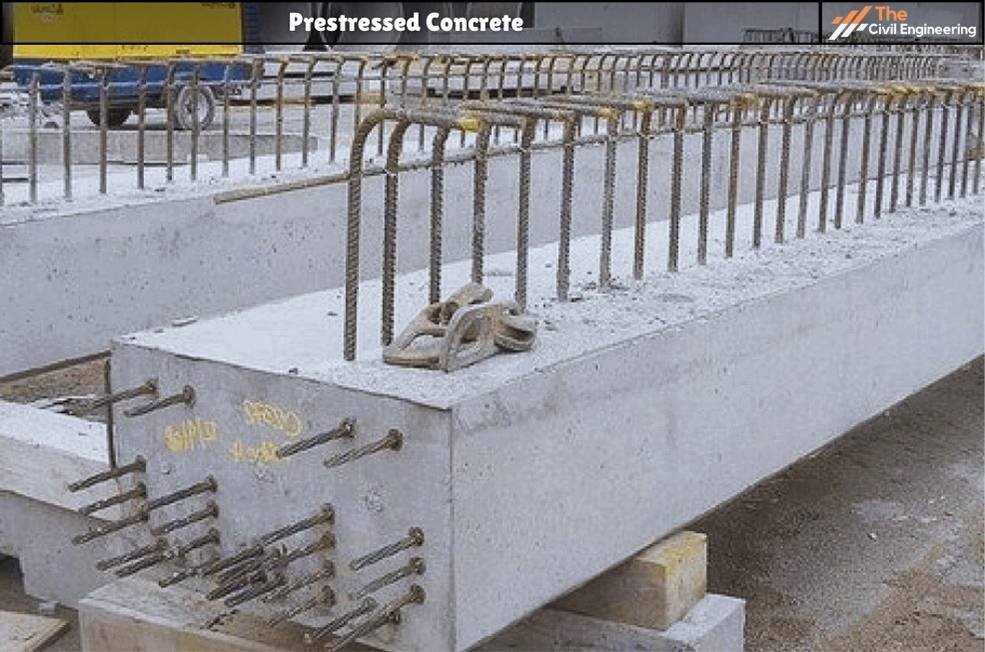

f. Prestressed Concrete

✓ It essentially consists of reinforcement bars that have been tensioned beforehand.

✓ In other words, the type of Concrete permits the inclusion of predetermined engineering stresses on it to counteract the stresses induced due to loading.

✓ The prestressed Concrete not only has considerable compressive strength but also has considerable tensile strength. This is ensured by utilizing the Concrete’s high compressive strength and the reinforcement bars’ high tensile strength.

✓ It is the most robust and most reliable type of Concrete. It is extensively used for massive structures constructions and various structural components such as columns, floor beams, and utilities such as railway sleepers, roofing, etc.

Some of the main advantages offered by prestressed Concrete can be listed as follows:

a. It offers a very high degree of durability and reliability.

b. It has higher strength and thus can withstand massive loads.

c. It requires fewer joints and lesser construction materials.

Some of the disadvantages of prestressed Concrete can be listed as follows:

a. Pre-tensioning of the reinforcement bars must be done before they are embedded in the Concrete.

b. Installing the prestressed Concrete requires special equipment and tools such as anchorage, jacks, and a highly skilled workforce.

c. The cost of prestressed Concrete is relatively higher.

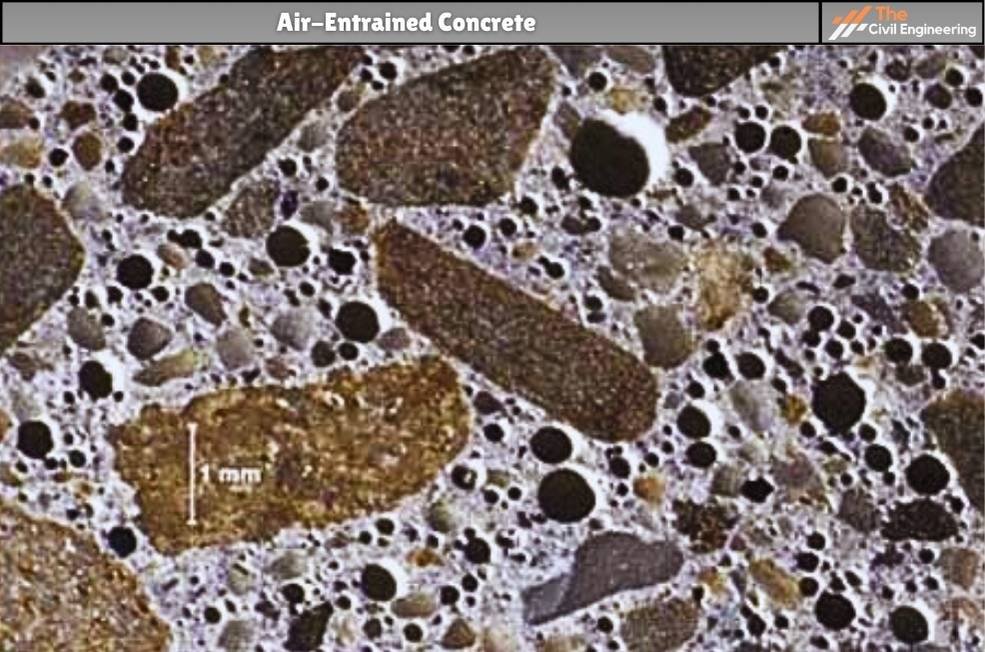

g. Air-Entrained Concrete

✓ Air-entrained Concrete comprises microscopic air bubbles comprising about 4 to 7 % of the total concrete volume.

✓ The air-entrained Concrete is manufactured using specific agents such as air-entraining admixtures and similar cement.

✓ The most common air-entraining agents include fatty acids, resins, and fatty alcohols.

✓ The air bubbles in the Concrete are microscopic with varying sizes.

✓ The primary purpose of adding the air bubbles in the Concrete is to remove or minimize the internal pressure by allowing space for the water to extend during the freezing of water.

Some of the advantages of air-entrained Concrete can be listed as follows:

a. It offers a high degree of resistance to alternate freezing and thawing actions.

b. It is less susceptible to deterioration by abrasion, shrinkage crack, and scaling.

c. It offers a greater degree of workability.

✓ However, the major drawback of the air-entrained Concrete is that adding the air-entraining agent significantly increases the porosity of the Concrete, thereby increasing the total unit weight of the Concrete.

h. Lime Concrete

✓ As the name itself implies, lime is used as binding material.

✓ It is a mixture of coarse aggregates, fine aggregates, and lime in a suitable proportion of water.

✓ Lime concrete was used extensively in ancient times.

Some of the essential properties of lime concrete can be listed as follows:

a. It is capable of withstanding considerable magnitude of loads.

b. It offers a high degree of plasticity as well as workability.

c. It has good resistance to weathering actions.

d. It also possesses significant waterproofing properties and volumetric stability.

e. The setting time of lime concrete is relatively longer.

f. It consumes less energy during production, and the carbon dioxide emitted is also lower.

Some of the advantages offered by lime concrete can be listed as follows:

a. It is cheap and readily available.

b. It is suitable for almost all types of load-bearing constructions, such as beams, columns, walls, etc.

c. Due to its waterproofing property, lime concrete can prevent dampness in floors and walls.

Some of the disadvantages of lime concrete can be listed as follows:

a. It takes a considerably longer time to set.

b.The curing period of lime concrete is also longer.

c. The time taken by the lime concrete to gain strength is longer.

i. Rapid Hardening Concrete

✓ As the name itself implies, it hardens within a very short period.

✓ The hardening time of such Concrete is only about 30 mins.

✓ Due to the quick hardening, the property is extensively used in construction works that must be completed quickly.

Some of the significant uses of rapid hardening Concrete can be listed as follows:

a. It is widely used for the repair of road pavements.

b. It is also used for underwater construction works.

j. Asphalt Concrete

✓ Asphalt Concrete comprises a mixture of aggregates and asphalt cement.

✓ Asphalt concrete is also commonly known as asphalt or blacktop.

✓ Generally, the composition of asphalt concrete consists of 90-95% of aggregates and 5-10% of asphalt cement.

✓ This type of Concrete also hardens within a relatively short period.

Some of the uses of asphalt concrete can be listed as follows:

a. It is widely used for the surfacing as well as repairing of highway pavements, runways in airports, and parking lots.

b. It is also used to construct the core of embankment dams.

k. Glass Concrete

✓ Glass concrete consists of binding materials and recycled glass as aggregates. It is a modern type of Concrete.

✓ The addition of recycled glass in the Concrete enhances the thermal insulation properties.

✓ Glass concrete is used for architecturally essential structures due to its aesthetic properties.

l. Roller Compacted Concrete

✓ Roller-compacted Concrete is lean Concrete placed and duly compacted utilizing heavy earthmoving equipment.

✓ The heavy roller is the most commonly used earthmoving equipment for this purpose.

✓ Roller-compacted Concrete consists of a minimal binding material, i.e., cement. Due to this reason, roller-compacted Concrete is mainly used for the filling and excavation works.

✓ Once the Concrete is placed, compaction is done to ensure the concrete gains high density and forms a hard monolithic block.

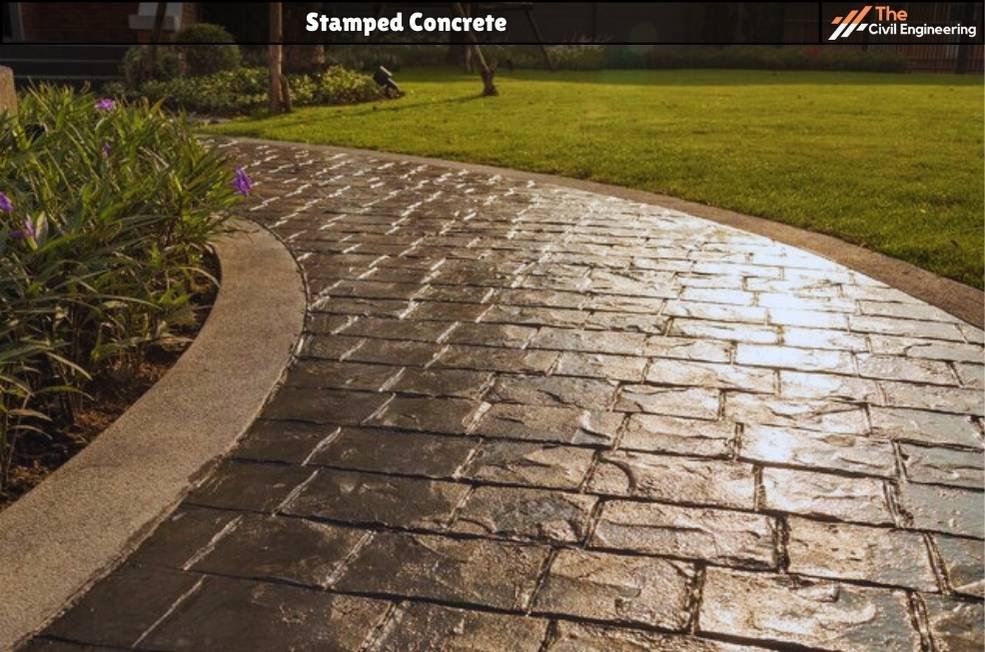

m. Stamped Concrete

✓ Stamped Concrete consists of aggregates, binding materials, and forged materials.

✓ Usually, stamps of various designs and pigments of different colors are added during the plastic state to the Concrete to increase the aesthetic appearance of the Concrete.

✓ The commonly used stamps are replicate stones, slate, flagstone, tile, brick, etc.

✓ Stamped Concrete is widely employed for architectural purposes such as patios, pool decks, driveways, etc.

Some of the advantages of stamped Concrete can be listed as follows:

a. It dramatically increases the aesthetic value of the constructions where it is used.

b. It is cheaper than pavers, bricks, and tiles.

c. stamped concrete offers excellent flexibility in terms of design and color.

d. It is pretty durable with a long life span.

Some of the disadvantages of stamped Concrete can be listed as follows:

a. It is more susceptible to developing cracks.

b. It requires relatively more maintenance and repair.

c. It is also prone to damage by the alternate freezing and thawing action.

n. Pumped Concrete

✓ Pumped Concrete is transported utilizing rigid pipes or flexible hoes at suitable pressure and directly discharged to the desired area.

✓ Mostly, such pumping of the Concrete is done when space is limited.

✓ The common types of pumping equipment used include piston-type concrete pumps, pneumatic-type concrete pumps, and squeeze pressure-type concrete pumps, and the conveying kit includes rigid pipes, flexible hoses, couplings, etc.

✓ The Concrete must be mixed into a very workable mix to pump it easily.

✓ A sufficient amount of fines are added to the blend for ease of conveyance and discharge.

✓ Pumped Concrete is extensively used for high-rise buildings where other means of concrete transportation are complex.

o. Vacuum Concrete

✓ In vacuum concrete, a significant amount of water is first added to the concrete mix. The mixture is duly poured into the formwork, and finally, the excess water is removed utilizing the vacuum pump or vacuum mats. Thus, the name vacuum concrete is given to this type of Concrete.

✓ The primary purpose of dewatering the excess water from the Concrete is to ensure early gain of strength of Concrete.

✓ Usually, the vacuum concrete gains its strength within 10 days.

Some of the advantages of vacuum concrete can be listed as follows:

a. The curing period of vacuum concrete is very short.

b. The bond strength of vacuum concrete is about 20% higher than that of ordinary Concrete.

c, The final strength of the vacuum concrete is also 25% higher than that of the ordinary Concrete.

d. Vacuum concrete has a relatively higher density.

e. This Concrete also hardens rapidly, and the formwork can be removed within thirty minutes of pouring the Concrete.

Some of the disadvantages of vacuum concrete can be listed as follows:

a. Vacuum concrete is more prone to damage by seepage and joint breakage.

p. Permeable Concrete

✓ As the name implies, it permits a certain amount of water to pass through.

✓ Permeable Concrete is designed such that it has high porosity.

✓ The void content in the porous Concrete is about 15 to 20% to ensure the passage of water.

✓ This type of Concrete is highly suitable for areas where the passing of runoff and stormwater exists.

✓ It is used extensively in sustainable construction techniques in parking areas, greenhouses, side lots, etc.

q. Shotcrete

✓ Shotcrete consists of a mixture of water, aggregates, and binding materials like ordinary Concrete but is sprayed pneumatically utilizing a nozzle.

✓ The shotcrete spraying is done at a high velocity to ensure a homogenous concrete mass.

✓ Apart from the regular constituents, the shotcrete also includes some additives, such as silica fumes, to improve its characteristics.

✓ If mixed and applied correctly, shotcrete develops high strength and is highly durable.

r. Ready-mix Concrete

✓ Ready-mix concrete is mixed and can be directly transported to the site.

✓ Such Concrete is prepared in the concrete plants and transported utilizing transit-mounted trucks.

✓ It is highly suitable when the works have to be completed within a short period.

Some of the advantages offered by ready-mix Concrete can be listed as follows:

a. It reduces the total time required to complete work, thereby ensuring the speed of construction.

b. The use of ready-mix concrete reduces the overhead costs of labor.

c. It reduces the possible wastage of materials and less impacts the environment.

s. Self Consolidated Concrete

✓ Self-consolidated Concrete is also called self-compacting Concrete (SCC).

✓ Self-consolidated Concrete is a highly flowable mix that can easily flow through the formwork.

✓ Thus, it does not require any form of mechanical consolidation.

✓ This type of Concrete is non-segregating in nature and offers a high degree of workability.

t. Fiber Reinforced Concrete

✓ Fiber Reinforced Concrete consists of aggregates, binding materials, and uniformly dispersed fibers.

✓ Mainly, the fiber used includes steel fibers with a diameter ranging from 10 to 20 microns and a length of 10 to 50mm.

✓ However, fibers made up of polymers, glass, carbon, etc, may also be used.

✓ The primary objective of adding such fiber is to increase the Concrete’s tensile strength, resilience, and flexibility.

✓ Fiber-reinforced Concrete is extensively used as overlays for road pavements, bridges, runways, etc.

u. Fly Ash Concrete

✓ Fly ash concrete essentially consists of fly ash.

✓ The fly ash may be used instead of fine aggregates, cement, or both.

✓ The most widely used replacement proportion is 30 % fine aggregates and 20 % cement.

✓ The most commonly used fly ash is obtained from finer coals than cement particles.

✓ The primary objective of adding fly ash is to enhance the workability and durability of the Concrete.

v. High-Strength Concrete

✓ High-strength Concrete is also commonly called high-performance Concrete (HPC).

✓ Concrete having a strength greater than 40N/mm² is known as high-strength concrete.

✓ In general, the strength of such concrete ranges from 60N/mm² to 80N/mm².

✓ The general composition of high-strength Concrete consists of aggregates, binding materials, water, and additives such as fly ash silica fumes, superplasticizers, etc.

Some of the essential properties of high-strength Concrete can be listed as follows:

a. It is very high strength and has good resistance to heavy loadings.

b. It also offers a high degree of resistance to fire hazards and shrinkage.

c. It has fair self-compacting property.

w. Silica Fume Concrete

✓ Silica Fume Concrete consists of silica fumes added to it.

✓ The silica fume is a finely divided particle mainly obtained as the by-product of silica.

✓ The silica fumes are, in actuality, six times finer than the cement particles.

✓ The primary objective of adding silica fumes is to reduce the pore spaces in the Concrete, thereby ensuring that the concrete gains high strength.

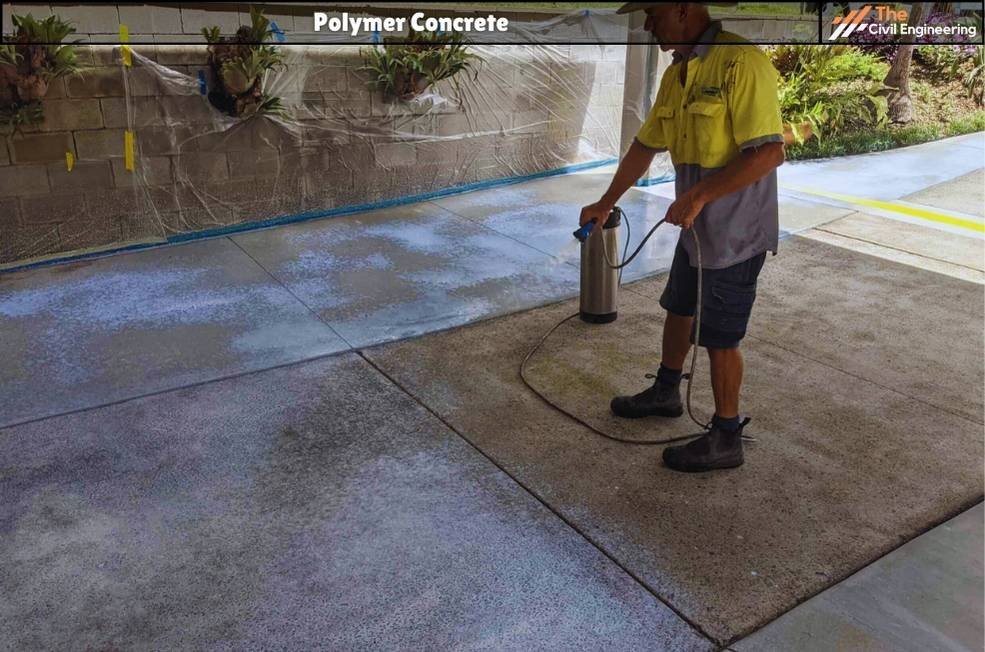

x. Polymer concrete

✓ Polymer concrete consists of additional substances known as polymers.

✓ The primary objective of this Concrete is the same as that of silica fume concrete, i.e., to increase the strength of the Concrete by reducing the pore spaces present in the Concrete.

✓ Polymer concrete can be further classified into the following types:

a. Polymer Impregnated Concrete

b. Polymer Portland Cement Concrete

c. Polymer Concrete

d. Partially Impregnated and Surface Coated Polymer Concrete

y. Ferro Cement Concrete

✓ Ferro cement concrete is a mixture of water, aggregates, binding materials (cement), and wire meshes.

✓ The wire meshes are impregnated into the cement concrete in a closely spaced manner.

✓ Primarily, steel wires of diameter ranging from 0.5 to 1mm are used to form such meshes.

✓ The primary objective of adding such wire meshes is to increase the tensile strength and ductility of the Concrete.

z. Pre-Packed Concrete

✓ Pre-packed Concrete is the type of Concrete in which the coarse aggregate is first packed into the formwork, followed by the pouring of cement-sand grout.

✓ Adding the cement-sand grout ensures that all the pores of the pre-packed aggregates are filled, thereby eliminating the shrinkage.

✓ Such type of Concrete is extensively used for large constructions with construction joints.

| Read More: Grades of Concrete |

| Read More: Concrete Admixtures |