1. Introduction

Compaction factor test on concrete i.e. compaction factor test can be defined as the test conducted on concrete to determine the workability of concrete in the laboratory where the maximum size of the aggregate does not exceed 38mm.

This test can also be efficiently used in the field.

The test was developed for the first time in the United Kingdom by the Road Research Laboratory.

The compaction factor test on concrete is a very sensitive test and can be used even for the concrete with very low workability which cannot be done by the slump test.

This test is known as the compaction factor test because the degree of workability is defined as the amount of work required for placing and compacting fully.

The compaction factor is also commonly referred to as the degree of workability and can be understood as the density ratio of concrete.

The compaction factor may be defined as the ratio of actual density obtained during the test to the density of the fully compacted concrete i.e.

Compaction Factor = Weight of partially compacted concrete / Weight of fully compacted concrete

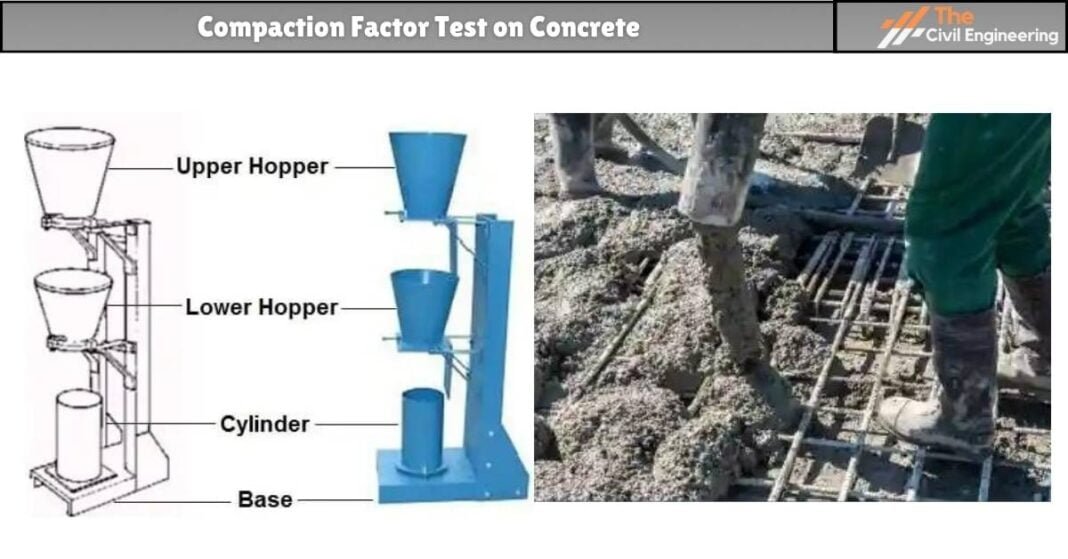

2. General Test Procedure Of Compaction Factor Test

The general test procedure of the compaction factor test on concrete is briefly described below.

Apparatus Required

1. Hand scoop having a length of 15.2cm.

2. Trowel.

3. A rod of a suitable material such as steel is rounded at one end.

4. A weighing balance.

Procedure

The test procedure consists of the following series of steps:

1. First of all, the concrete sample of the appropriate mix is prepared.

2. The concrete sample is then placed on the upper hopper up to its brim using the hand scoop. It is then thoroughly leveled.

3. The cylinder is duly covered.

4. The trap door at the bottom of the upper hopper is opened to allow the concrete to fall under the lower hopper.

5. Similarly, the trap door at the bottom of the bottom hopper is opened so that concrete falls on the cylinder below.

6. Then, the excess of the concrete is removed and the top surface of the concrete is leveled properly.

7. The outside of the cylinder is thoroughly cleaned.

8. The cylinder along with the concrete is weighed to the nearest 10 grams. This weight is the weight of the partially compacted concrete denoted as W2.

9. Then, the cylinder is emptied and again refilled with the same mix of the concrete in layers that are approximately 5 cm deep, and each layer is rammed properly to obtain the full compaction.

10. The top surface of the concrete is duly leveled.

11. The cylinder along with the concrete is weighed. This weight is the weight of the fully compacted concrete denoted as W3.

12. The weight of the empty cylinder (W1) is then taken.

Observation & Calculation

Result

The value of the compaction factor must range from 0.78 to 0.95.

| Workability | Compaction Factor | Slump (mm) |

|---|---|---|

| Very Low | 0.78 | 0 – 25 |

| Low | 0.85 | 25 – 50 |

| Medium | 0.92 | 50 – 100 |

| High | 0.95 | 100 – 175 |

| Read More: Soil Tests for Road Construction |

| Read More: 5R Principle of Solid Waste Management |