In this article, we will discuss the apparatus required, procedures carried out, and calculations that are done in compression test on brick.

1. What is the Compressive Strength of Brick?

The compression strength of the brick is the ratio of maximum load at the failure to the cross-sectional area of the brick.

Mathematically,

Co=P/A

Where,

Co = Compressive Strength of Brick

P = Maximum Load at Failure

A = Cross-sectional Area of Brick

The crushing or compressive strength of normal building bricks should not be below 3.5 N/mm². The bricks of high quality should not have strength below 14 N/mm².

The compressive strength testis also known as the crushing strength test which is an important type of laboratory test conducted on bricks to determine the load-carrying capacity of bricks when subjected to a compressive load.

This test is performed utilizing a compression testing machine.

2. Apparatus & Materials Required

1. Compression Testing Machine

2. Sample of whole bricks

3. Cement, sand, and water for mortar preparation

3. Procedure of Compression Test on Brick

( Note: In the absence of a compression testing machine, the compressive strength of the brick can be judged roughly by applying the force required to break the brick with the hammer.

The brick also should not break when fallen on its end on the ground from the height of 2 m. )

a. Specimen Preparation

i. The samples of whole bricks are first taken and the unevenness is removed.

ii. The dimensions are duly measured.

iii. The samples are then immersed in water for 24 hours at room temperature. After 24 hours, the specimen is removed and dried.

iv. If traces of water are still present, it is wiped out with a clean cloth.

v. Then, cement mortar is prepared and the frog of the specimen is filled with the prepared cement mortar.

vi. Any voids present are also filled with cement mortar ( Commonly 1:3 cement mortar).

vii. The mortar-filled bricks specimen is then stored in damp jute bags for 24 hours.

viii. Then, keep the bricks in water for 3 to 7 days. This is to permit the mortar to harden.

b. Testing of the Sample

i. Keep the bricks out of the water, permits the water to drain, and clean the surface with a clean cloth. When the surface of the brick is dry, each brick is tested for compressive strength one by one.

ii. The specimen with the mortar-filled face upward is placed in between the plates of the compression testing machine.

iii. The load is then applied axially at a uniform rate of 14N/ mm² per minute until failure occurs. The maximum load at failure is recorded.

iv. The maximum load at failure (P) is divided by the cross-sectional area of brick (A) of the brick to get the compressive strength (Co) of brick. Mathematically,

Co=P/A

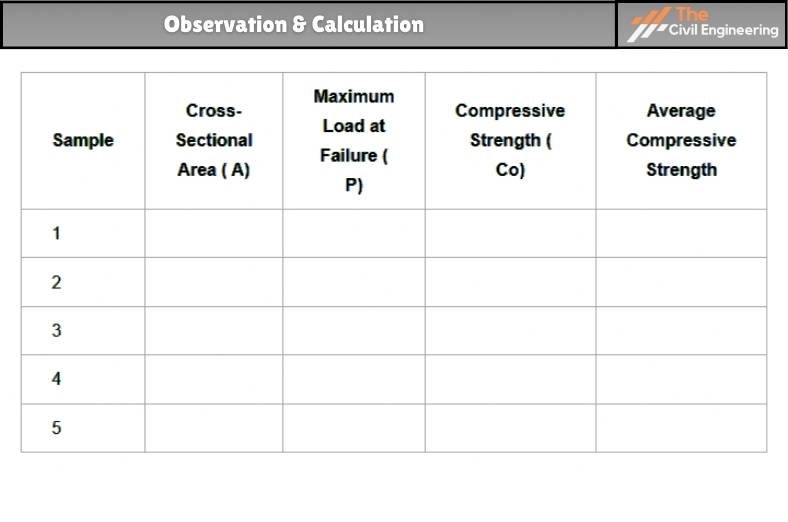

v. The arithmetic mean of the compressive strength of all the five bricks shall be considered as the compressive strength of that lot of bricks. But not for all the bricks of a kiln.

4. Observation & Calculation

5. Result

Compressive Strength of Given Lot of Bricks = ……………. N/mm²

6. Brick Classification Based on Compressive Strength

| Bricks Class Designation | Average compressive strength of Bricks | |

| Not less than (N/mm2) | Less than (N/mm2) | |

| 350 | 35 | 40 |

| 300 | 30 | 35 |

| 250 | 25 | 30 |

| 200 | 20 | 25 |

| 175 | 17.5 | 20 |

| 150 | 15 | 17.5 |

| 125 | 12.5 | 15 |

| 100 | 10 | 12.5 |

| 75 | 7.5 | 10 |

| 50 | 5 | 7.5 |

| 35 | 3.5 | 5 |

| Read Also: Soundness Test of Cement | Lab Test Procedure |

| Read Also: Slump Test of Concrete |