1. Introduction

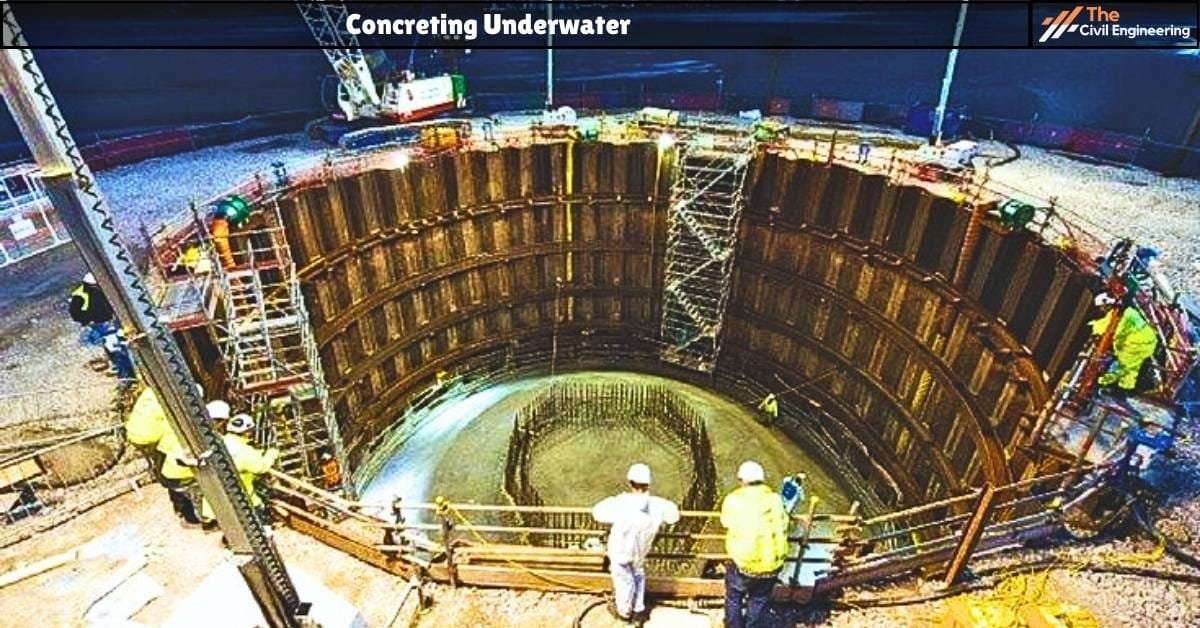

Concreting underwater is a very complicated task. It may be required in the case of deep foundations and marine works. Concreting underwater methods are briefly explained below.

The placing of concrete underwater is usually confined to plain concrete (not reinforced) construction because of the danger of loss of cement and segregation of concrete. The use of the following methods is restored, under the circumstances when the provision of cofferdams, caissons, or other such dewatering measures are difficult to practice.

2. Concreting Underwater Methods

a. By tremie:

~ Tremie is the name given to a steel pipe having a diameter of 150 mm to 300 mm and sufficiently long to reach the bed of the watershed keeping its one end above the water level.

A hopper is provided at its upper end for pouring concrete inside the pipe. The tremie is equipped with a check valve at its lower end.

~ When the concrete is poured into the hopper of the pipe, it displaces the air and water from the pipe and reaches the bed.

~ The tremie, during the process of concrete, is gradually raised keeping the lower end of the pipe submerged in the concrete mass already poured below.

~ A rich mix of concrete should always be used so that the possible loss of cement underwater is compensated.

~ It should be borne in mind that concrete thus laid underwater should never be compacted or consolidated.

b. By ship or bottom opening bucket:

~ In this method, a cubical hinged bottom bucket or cylindrical bucket equipped with a rolling gate or a ship is used for concreting underwater.

~ To minimize the concrete loss during the process of placing, it must be ensured that the bucket or ship is lowered to the bed of the working place before the concrete is discharged.

c. Placing in bags:

The method consists in partially (usually about two-third) filling of cloth or gunny sacks with concrete, and trying them in such a way that they can readily be accommodated in a profile of the surface on which they are placed.

The properly filled bags are lowered into the water and placed carefully in a header and stretcher fashion as in brick masonry construction with the help of drivers.

The advantages of this method are that, in several cases, no framework is necessary, and a comparatively lean mixer may be used provided sufficient plasticity is retained.

The disadvantages of this technique are:

i. The accurate positioning of the bags in place can be accomplished only by the divers; the work is consequently slow and laborious.

ii. Voids between the adjacent bags are difficult to fill, there is little bonding other than that achieved by the chemical interlock between bags.

iii. The method is only suited for placing the concrete in rather shallow water.

d. Prepacked Concrete:

Prepacked concrete is also called grouted concrete.

It consists of placing the coarse aggregate only in the forms and thoroughly compacting it to form a prepacked mass.

Thus formed mass is then grouted with cement mortar of the required proportions.

The aggregate should be wetted before being placing.

The mortar that grouts the concrete fills the voids by displacing water.

This technique is very much suited for underwater construction, repair, and maintenance of mass structures such as spillways, dams, etc.

| Read More: Pile Construction |

| Read More: Components of Bridge |