THE DETERMINATION OF DRY DENSITY BY THE CORE CUTTER METHOD GENERALLY INVOLVES THE HAMMERING OR JACKING OF A STEEL CYLINDER ( WITH KNOWN MASS AND VOLUME) INTO THE SOIL THEREBY DETERMINING THE MASS OF THE SOIL.

This method is used for dry density determination.

This method is not desirable for coarse-grained soil or coarse-grained pavement materials.

1. Suitability of Core Cutter Method

✔ This method of dry density determination is most desirable for cohesive soil.

✔ It is only used on fine-grained cohesive soils that do not contain stones.

2. Objectives of the Core Cutter Method

✔ The primary objective of the core cutter method is to determine the dry density of soil.

✔ It is used as a control test to check if the soil has acquired the designated dry density or not.

✔ The determined in situ dry density is necessary for the design of pavement and highways.

3. Apparatus Required

1. A steel rammer of mass of 9kg and an overall length including the foot and staff of about 900 mm.

2. A cylindrical core cutter with a 100 mm internal diameter and 130 mm long.

3. Weighing balance with an accuracy of 1 gram.

4. Steel dolly with 100mm internal diameter and 25 mm high.

6. Straight edge, ruler of steel, etc.

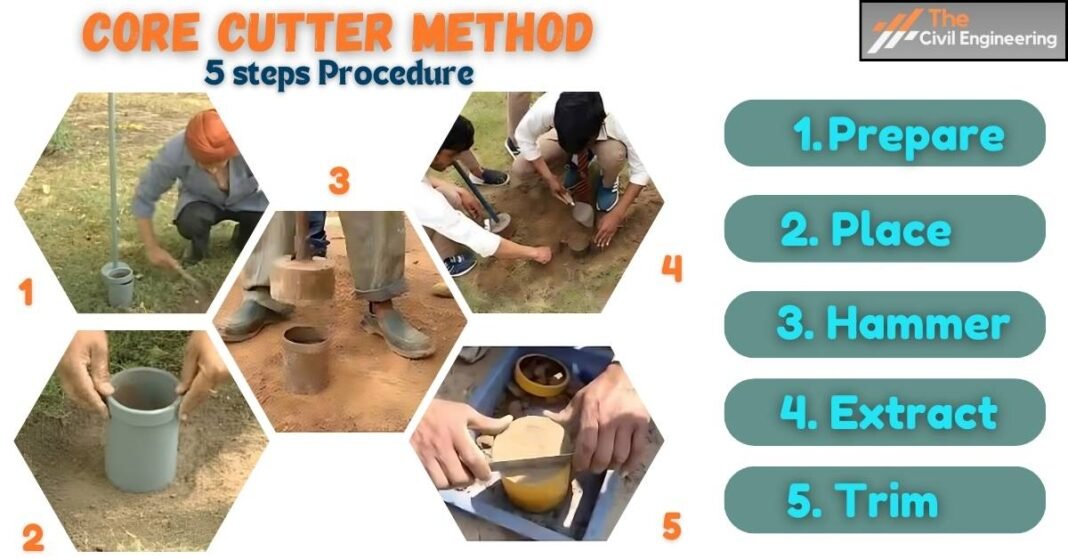

4. Procedure

The procedure for the dry density determination by the core cutter method involves the following series of steps:

i. The experimental setup of the cylindrical core cutter is first made.

ii. The steel dolly is then placed over the cutter to prevent damage to the edges of the core cutter.

iii. The cylinder is then embedded into the ground up to its full height with the help of a rammer and is taken out by excavating its sides without disturbing the sample.

iv. The surplus soil at both ends is trimmed and the weight of the cylinder with soil is determined.

v. Then, from the known dimension of the cutter, volume is determined.

vi. Moisture content of the soil is determined with theoven drying method.

vii. The dry density of the soil is then computed using the following formula:

Bulk Density (γt) = (W2 – W1 ) / V

Dry Density (γd ) = γt / ( 1 + W)

Where,

W1 = Weight of cutter

W2 = Weight of the soil + cutter

W2 – W1 = Weight of soil

V = Volume of the cutter

5. Observation and Calculations

| Sl. No. | Observations and Calculations | Determination No. | ||

| 1 | 2 | 3 | ||

| Observations | ||||

| 1 | Core cutter No. | |||

| 2 | Internal diameter | |||

| 3 | Internal height | |||

| 4 | Mass of empty core cutter (M1) | |||

| 5 | Mass of core cutter with soils (M2) | |||

| Calculations | ||||

| 6 | M= M2 – M1 | |||

| 7 | The volume of cutter V | |||

| 8 | Water content | |||

| 9 | Dry density using the formula | |||

6. Results of the Core Cutter Method

The dry density of the soil= _______ g/ml.

7. Advantages of the Core Cutter Method

The advantages of the core cutter method are as follows:

1. This method is relatively fast and simple.

2. Core cutter test can be carried out in the natural environment without sampling disturbance.

3. It is highly suitable for the dry density determination of cohesive soil as well as soft, fine-grained soils.

8. Disadvantages of the Core Cutter Method

The disadvantages of the core cutter method are as follows:

1. This method is only practicable at places where the surface of the soil is exposed and the cutter can be easily driven.

2. It is not suitable for cohesionless soil.

9. Precautions Taken While Performing Core Cutter Method

The precautions that need to be followed during this test are listed below:

a. Soil around the core cutter should be removed before lifting the core cutter. This is done to minimize the disturbances.

b. This test should be performed only on fine-grained cohesive soils.

c. Core cutter should be driven into the ground till the steel dolly penetrates the ground halfway only so as to avoid compaction of the soil in the core.

10. References1. Content Filter & Authenticity Checking Team, The Civil Engineering (Our team checks every content & detail to maintain quality.) |

| Read More: In-Situ Dry Density By Sand Replacement Method |