| There are 8 types of defects in painting that commonly occur. This article will discuss all eight types with causes and repair. |

Painting is an important finishing work that is necessary to increase the aesthetic value of any structural construction.

The painting also provides an outer protective coat or layer to the structure that protects the surface from various atmospheric factors such as frost, sunlight, rainfall, and so on, as well as from various infiltrative actions such as corrosion, decaying, weathering, etc.

The absence of regular maintenance and the use of poor-quality paint may lead to the rise of defects in painting.

1. Defects In Painting

Some of the defects in painting work can be summarized as follows:

i. Fading

Fading is a common defect in painting work that causes the discoloration of the applied paint.

The main causes of such defects are the various atmospheric factors such as rain, sunlight, moisture infiltration, etc.

Precisely, fading may be defined as losing one or more color pigments from the paint film.

Over time, the paint film loses color pigments under harsh atmospheric conditions and continuous sun exposure.

fig: Fading

Causes of Fading

The main causes of fading are:

1. Sunlight, Infrared and Ultraviolet Radiation

2. Temperature Variations

3. Application of dark color paints (darker colors tend to absorb more radiations from the sunlight)

4. Coastal and Harsh Environmental Conditions

5. Inadequate Film Thickness

6. Use of inferior-quality paints

Repair & Prevention of Fading

Once fading of the paint coat begins, it cannot be repaired completely, but weathering-resistant pigments may be used to prevent further de-coloration.

Some of the precautions that can be taken to prevent fading are:

1. Use of certified UV-resistant paints from authorized manufacturers.

2. Selection of lighter-colored paints.

3. Regular maintenance and supervision.

ii. Peeling and Blistering

Blistering of paint is a defect that causes swelling of the paint film.

The actual reason behind the swelling of the paint film is the formation of air bubbles beneath the coating of paint due to the ingress of moisture, oil, or grease matter.

If the swelling of the film of paint occurs due to grease or oil, then it is known as blistering.

fig: Blistering

On the other hand, if the swelling of the paint film occurs due to water or moisture, it is known as peeling.

Usually, the swelling is caused due to the use of excessive oil during the application of the final coat, inappropriate seasoning of timber, trapping of gases beneath the coat of paint etc.

fig: Peeling

Causes of Peeling & Blistering

Some of the causes of the peeling and blistering of paint can be listed as follows:

1. Excessive moisture

2. High humidity

3. Excessive layers of paint

4. Lack of surface preparation before application

5. Use of poor-quality paint

6. High temperature

7. Long exposure to sunlight

8. Use of inappropriate application techniques.

Repair & Prevention of Peeling & Blistering

Such defects can be prevented using porous paints such as emulsion paints instead of non-porous paints.

The coat of paint subjected to excessive peeling and blistering can be repaired as follows:

1. First of all, the working space must be cleared. All the furniture and utilities must be covered.

2. Then, the area of the paint coat where peeling has occurred must be scraped off using a wire brush or paint scraper.

3. The surface is then prepared for the application of a new coat, including plastering of cracks, if any, cleaning of the surface, etc.

4. An appropriate primer is then applied to the prepared surface.

5. The final coat of paint is then applied.

iii. Running

Running of paint is a type of defect in painting work that occurs when the surface to be painted is too smooth.

In this type of defect, due to excessive smoothness, the paint runs back, leaving behind some uncovered surfaces.

fig: Running

Causes of Running

Some of the causes of the running of paint can be listed as follows:

1. Low viscosity

2. Excessively glossy surface

3. Application of too-wet paint

4. Irregular spraying action

Repair and Prevention of Running

Such defects can be prevented using appropriate spraying techniques, smaller nozzles, etc.

The repair work includes the following steps :

The paint is first allowed to dry completely.

After it has dried completely, the run is removed with wet sandpaper, carbon block, or sand block.

Then, the surface must be finely polished and compounded.

The surface is finally treated with high-gloss polish.

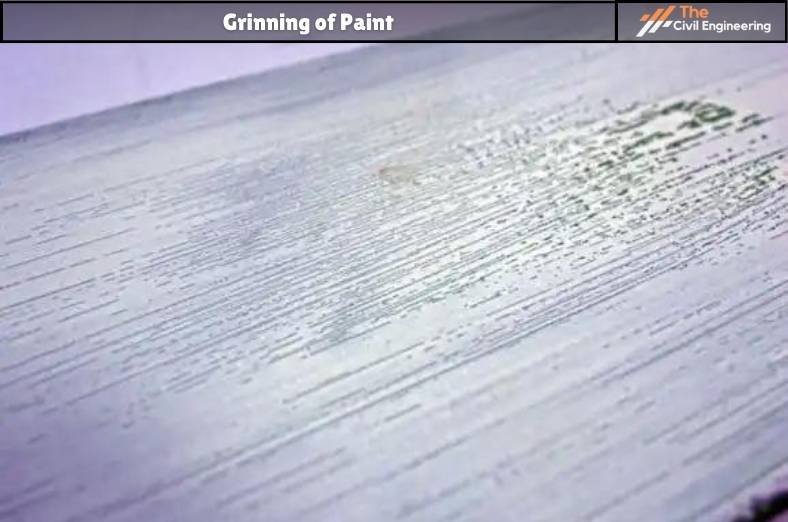

iv. Grinning

In the absence of adequate thickness of the final coat of paint, the background becomes visible. Such a defect is known as the grinning of paint.

Grinning occurs when the paint coat is not opaque enough to cover the background, i.e. due to the low opacity of the final coat of paint. Thus, the underlying surface becomes visible.

fig: Grinning

Causes of Grinning

Some of the causes of grinning of paint can be listed as follows:

1. Inadequate thickness of the final coat

2. Insufficient volume of paint

3. Low-opacity paint

4. Use of strong color in underlying coats

Repair and Prevention of Grinning

This defect can be prevented by ensuring the use of adequate thickness and volume of the final coat.

The repair work includes the following:

1. The grinned surface is first thoroughly cleaned.

2. Then, another paint compatible with the grinned surface is

selected and duly applied to the defective surface.

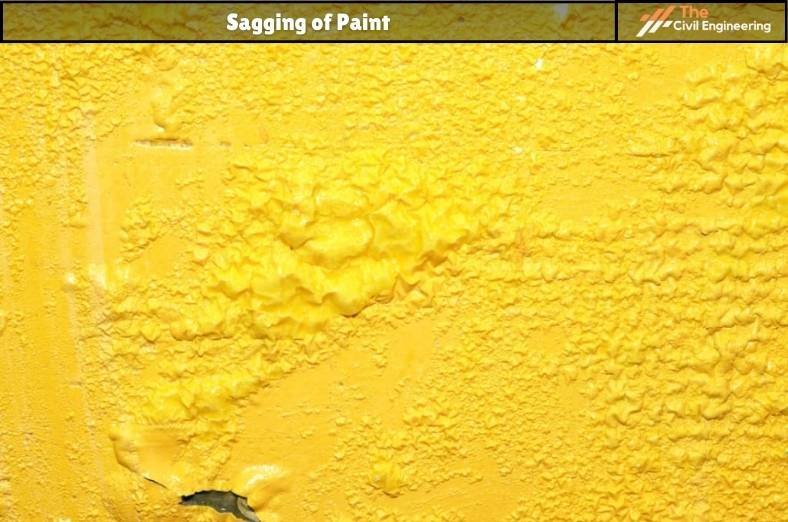

v. Sagging

Sagging is associated with applying a thick layer of paint on an inclined or vertical surface.

It is the type of defect in which the layer of paint applied falls downwards, i.e. sags down from the surface.

fig: Sagging

Causes of Sagging

Some of the causes of the sagging of paint can be listed as follows:

1. The excessive thickness of the coat

2. Poor workmanship

3. Lack of surface preparation

4. Inappropriate spraying technique

5. Low viscosity

Repair and Prevention of Sagging

Such a defect can be corrected by the following steps:

1. When the paint is still wet, it is rolled out or brushed out immediately to cover the surface evenly. If the paint has already dried, it must be removed using sandpaper, and a new coat must be applied.

2. The painting must not be carried out during cold or humid conditions.

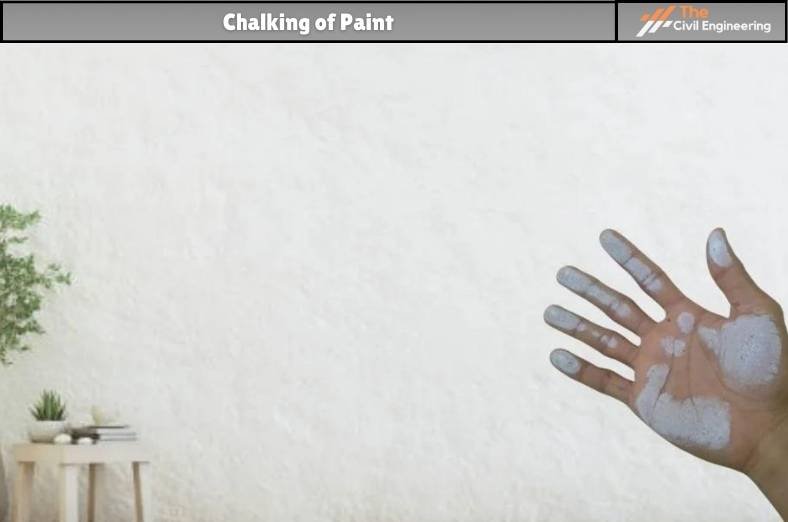

vi. Chalking

Chalking is the defect resulting in powder-like substances forming on the paint’s surface.

The main reason behind the chalking of paint is insufficient oil in the primer.

fig: Chalking

Causes of Chalking

Some of the causes of chalking can be listed below:

1. Use of inferior-quality paint

2. Long exposure to sunlight and ultraviolet radiation

3. Alternate hot/cold temperature

Repair and Prevention of Chalking

Once chalking occurs, it cannot be undone.

To eliminate the defect, the surface must be pressure washed or scrubbed to remove the surface contaminants.

Some of the preventive measures that must be adopted to prevent chalking are as follows:

1. Use of water-based paints

2. Use lighter shades of paint

3. Regular maintenance

vii. Flaking

The type of defect in which the paint film detaches from the surface is known as paint flaking.

In general, flaking may be understood as the phenomenon in which the paint coat does not stick properly on the surface.

The main reason behind the flaking of paint is the lack of adequate bonding between the surface and the film of paint.

fig: Flaking

Causes of Flaking

Some of the causes of flaking can be listed as follows:

1. Poor paint adhesion

2. Inadequate pre-cleaning before application

3. Ingress of moisture

4. Use of inferior-quality paint

Repair and Prevention of Flaking

To prevent the flaking of paint, the surface must first be cleaned properly and rubbed with abrasive paper before applying paint.

The flaking of paint can be corrected by following the below-mentioned steps:

1. Firstly, the flaked surface must be examined and thoroughly

cleaned.

2. The surface is rubbed and cleaned using sandpaper.

3. Then, the surface is treated with a prime coat.

4. Finally, the surface coat is applied.

viii. Blooming

Blooming is the type of defect that causes dull patches on the surface.

The blooming of paint results in the appearance of a whitish patch on the outer surface of the paint.

Generally, water is collected after condensation, and the water-soluble compounds migrate to the coated surface from the body of paint.

When such molecules evaporate from the surface, it results in the formation of a dull patch.

The main cause behind the blooming of paint is the poor quality of paint and improper ventilation.

fig: Blooming

Causes of Blooming

The causes of the blooming of paint can be listed as follows:

1. Use of fat thinners

2. Excessive humidity level

3. High air pressure

4. Poor workmanship

5. Use of inferior-quality paint

6. Poor air movements

Repair and Prevention of Blooming

The preventive measures for avoiding the blooming of paint can be listed as follows:

1. The temperature must be maintained at 68°F to 78°F as far as possible.

2. Use of good quality paint, retarder, thinner, etc.

3. Reduction of air pressure.

This was for the Defects In the Painting.

2. References1. Content Filter & Authenticity Checking Team, The Civil Engineering (Our team checks every content & detail to maintain quality.) |

Read Also: Earthquake Proof Buildings