1. Introduction

Concrete technology is a growing construction technology and widespread in all parts of the world. In simple terms, concrete is a mixture of cement, sand, and aggregate in a definite proportion. When water is added to such a mixture, hydration takes place resulting in a hard mass which is known as concrete. Due to the immense use of concrete structures, it is necessary to ascertain the quality of concrete in the construction. One such test includes the determination of the modulus of elasticity of concrete.

The modulus of elasticity of concrete, in general, refers to the ratio of the applied stress on the concrete to the strain-induced.

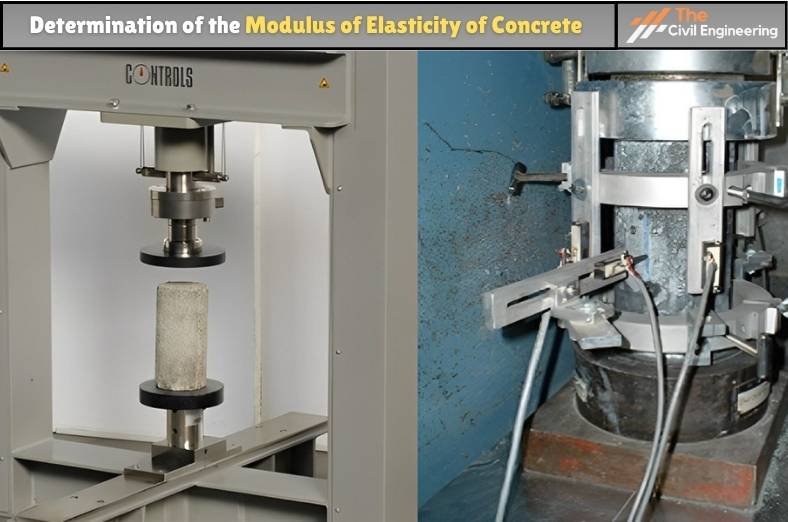

The test for determining the modulus of elasticity of the concrete is known as a compression test on the cylindrical concrete sample.

The test typically consists of an arrangement of the compressometer and applying a series of compressive stress cycles up to about 40% of the measured compressive stress.

2. Objective

To determine the Modulus of Elasticity of Concrete.

3. Theory

The basic principle of this test is based on the evaluation of the deformation of the concrete specimen under various loading conditions.

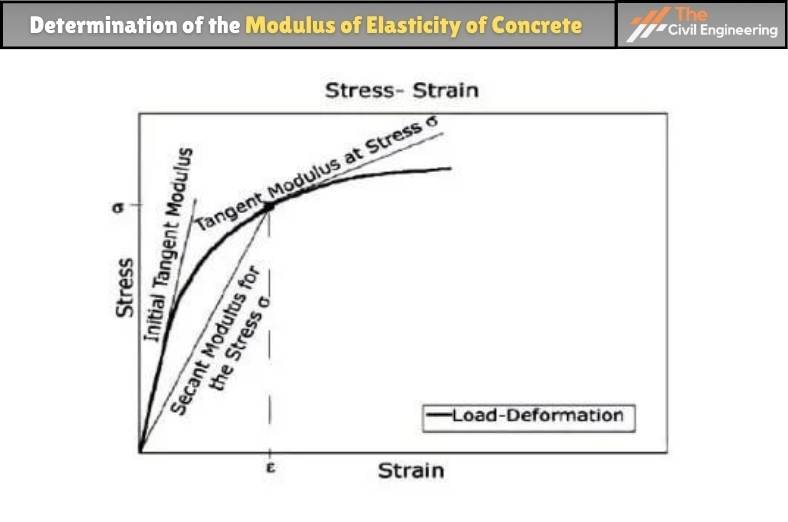

Based on these observations, the stress-strain graph is plotted and the modulus of elasticity is obtained.

The stress-strain graph is also commonly known as the load-deflection graph.

Then, the slope of a line is drawn in the stress-strain curve from a stress value of zero to the compressive stress value computed as 0.45f‘c gives the modulus of elasticity of concrete.

4. Procedure

The procedure for determining the modulus of elasticity consists of the following series of steps:

1. Setting up of Compressometer:

The first step includes the setting up of the compressometer.

Compressometer can be defined as the device employed for assessing the strain and deformation behavior of the cylindrical concrete specimen.

The setup includes the following steps:

i. The top and bottom frames of the compressometer are adjusted using the spacers.

ii. The pivot rod is then kept on the screws and is duly locked in position firmly.

iii. Then, the compressometer is placed carefully at the center of the specimen.

iv. The screws are tightened while the compressometer is held in position.

v. Finally, after completion of the positioning, the spacers are unscrewed and removed.

2. Testing of the Specimen:

The testing of the specimen mainly consists of the following steps:

i. After the specimen is properly placed, the load is applied at the rate of 140 kg / cm² /minute.

ii. The application of load is continuously increased until the stress value equal to (c+5)kg/cm² is attained. C indicates 1/3rd of the average compressive stress.

iii. Once, the above value is achieved, the load is held for about a minute. The stress is then reduced to 1.5 kg/cm².

iv. Similarly, the loading rate is increased to (c+1.5) kg/cm² and the reading is recorded.

v. The load is increased similarly at 1T interval and recorded.

vi. The graph is then plotted using the obtained values.

5. Calculations

Fig: Stress-Strain Graph

1. Slope of the tangent at working stress gives,

Tangent modulus at working stress=stress/strain

2. Slope of the line joining tangent point and point of working stress gives,

Secant modulus= stress/strain

6. Result

Initial tangent modulus of concrete=…….N/mm 2

Tangent modulus at working stress=……..N/mm 2

Secant modulus (modulus of elasticity of concrete) =…….N/mm 2

7. Precautions

1. Readings should be taken immediately and continuously without any delay.

2. Test may require to be repeated if the strain readings differ by more than 5%.

| Read More: Tension Test on Steel Rod |

| Read More: Setting time of cement |