1. Introduction

Distemper paint is basically water-based paint that consists of a mixture of water, chalk, and pigments. It is used as the early form of whitewash but in actual it is better than a regular whitewash.

In the distemper paint, mostly the raisins and animal glue are used as the binding materials.

The distemper paint provides a smooth finish to the surfaces. It is also commonly referred to as cement paint. This is because the distemper paint can be applied directly on the plastered walls without the use of any prime coat.

The distemper paint is available in both the powder form and the paste form in the market. It is comparatively cheaper and can last as long as five years.

2. Composition of Distemper Paint

The composition of the distemper paints includes the following:

i. Base/Body:

Chalk or lime is used for the base of distemper paint.

ii. Vehicle/Binder:

Various types of resins such as acrylic resins, alkyl resins, and epoxy resins are used as vehicles in the distemper paint.

iii. Inert Filler/ Extender:

Various coloring pigments are used as the extenders in the distemper paint.

Usually, the coloring pigments used are larger in size than the ordinary secondary fine particles.

iv. Pigment:

Mostly, the powdered mineral colors are used as the pigment in the distemper paints.

v. Thinner/Solvent:

In the distemper paint, the solvent used is water.

vi. Additive:

Mostly, the alkali resistance substances are used as additives in the distemper paint.

3. Features of Distemper Paint

i. It has a distinct property by the virtue of which it allows the moisture to escape from the surface to which it is applied.

ii. It is easy to apply and can be applied directly on the plastered surface.

iii. A small amount of thinner must be added to the distemper paint during its application as this type of paint is not manufactured in ready-to-use form. The thinner mostly used for this purpose is water.

iv. It can easily be cleaned by using a mild solution of detergent.

v. It is not flexible in nature.

vi. The life span of the distemper paint can range from three years to five years.

vii. It is not water-resistant but provides a matte smooth finish.

viii. It has low VOC content.

ix. It provides a coverage of approximately 4.5 to 5 sq. mt./ltr for about two coats. However, the coverage depends upon the methods and condition of application, surface roughness, and porosity.

x. It is available in a wide range of colors in packs of 1kg, 2kg, 5kg, 10kg, and 20 kg packs.

4. Advantages

Some of the advantages offered by the distemper paint can be listed as follows:

i. It gives an aesthetically pleasing matt finish to the surfaces.

ii. It is economical and easily available in the market.

iii. It can be used for both the interior and exterior walls.

5. Limitations

The limitations of distemper paint can be listed as follows:

i. It can be easily scraped off.

ii. It is not suitable for high traffic areas.

iii. It is not water-resistant.

iv. If thinners are not added to the distemper paint before use, then various defects such as brush mark defects, sagging defects, etc may occur.

6. Application of Distemper Paint

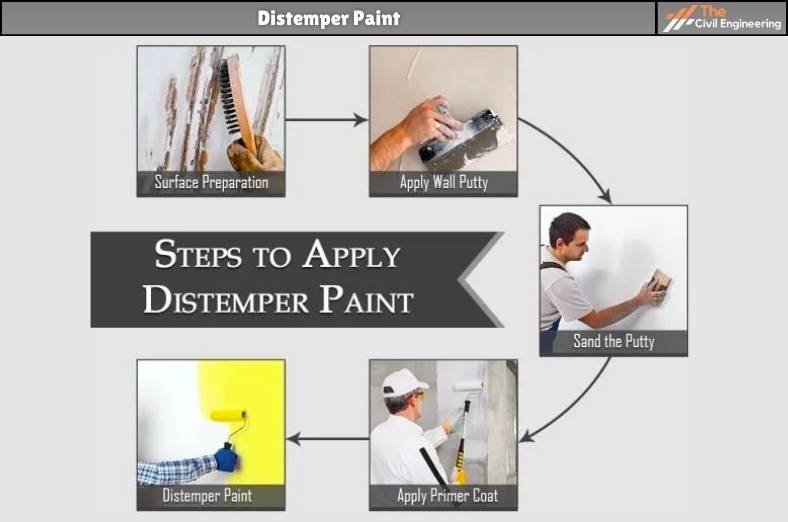

The application procedure of the distemper paint includes the following steps:

A. Preparation of the Surface:

The first step includes the preparation of the surface. The surface may be a new one or an old surface. The preparation for the two different surfaces can be listed as follows:

i. Preparation of New Surface:

At first, the plastered surface must be allowed to cure completely.

Usually, the curing period must be 28 days.

After the surface has cured completely, all the dust particles, dirt, grease, mortar dropping, etc that may be present in the surface must be cleaned utilizing a wire brush or putty knife.

Then, the surface must be cleaned with a dry cloth.

ii. Preparation of Old Surface:

When the distemper paint is to be applied on an existing surface, the surface must be made free from all the dust particles, grease, dirt, mortar droppings, etc utilizing a putty knife or wire brush.

Then, the cleaned surface must be rubbed thoroughly with sandpaper and the entire surface is washed and allowed to dry fully.

The holes and the cracks are then filled with putty and left for hardening.

Finally, the surface is again rubbed with sandpaper to obtain a smooth surface and wiped off with a dry cloth.

B. Application of Wall Putty:

Then, a coat of primer is applied on the cleaned surface which is allowed to dry overnight.

After it has dried completely, a coat of putty must be applied.

It must be taken care that the first coat of the putty must be applied in a bottom to top manner i.e. vertical manner.

It must be done by using a putty blade, spatula, or trowel.

Then, it is allowed to dry for a period of about 6 to 8 hours.

After complete drying of the putty, the surface must be rubbed with sandpaper to obtain a smooth surface and remove the unevenness.

Then, another coat of putty may be applied and it must be allowed to dry completely for 8 to 12 hours.

However, the drying period may be varied as per the temperature variations, humidity, thickness, etc. After complete drying of the second coat, the surface must be rubbed very gently to remove unevenness using sandpaper.

The minimum thickness of each coat must be at least 1.5mm.

C. Application of Primer Coat:

After the application and drying of the putty, the primer coat is applied.

This is done to ensure that the surface bonds well with the distemper paint. The prime coat acts as a foundation for the paint. The primer coat can be applied employing a brush or roller.

After the drying of the first coat, the second coat is applied and allowed to dry for 8 to 12 hours.

D. Application of Distemper Paint:

Firstly, the paint is diluted according to the specified dilution ratio by the manufacturer.

Then, the first coat of the distemper paint is applied utilizing a brush or roller and allowed to dry for a period of about 12 to 16 hours.

Then, the second coat of the distemper paint is applied and allowed to dry overnight.

| Read More: Aluminium Paint |

| Read More: Defects in Paint |