In this article, we will discuss dowel bars.

1. Introduction

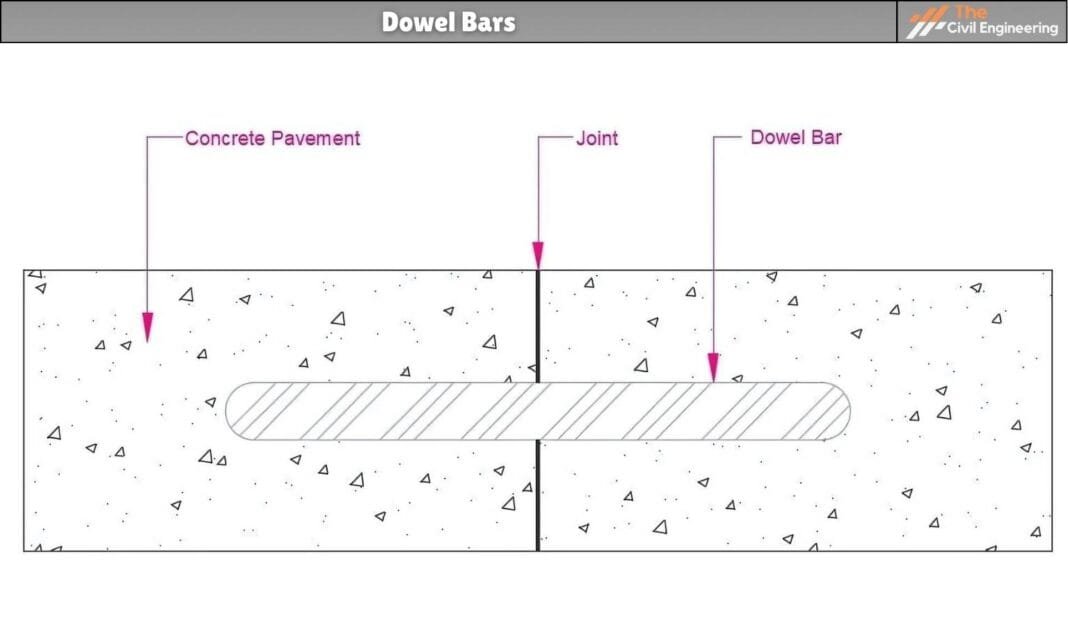

Dowel bars are the steel left portion to joint of any members such as slab, column, and stairs, etc. to transport the load of inducing in the concrete members. Dowels bars are the steel, rod bar, or rebar that is left as per to diameter of steel.

Dowel bars are round steel that is placed across horizontal joints of concrete members important to keep as load transfer factor across concrete joints, it also allows movement to act. It can be placed where movement is on purpose-designed for joints of longitudinal.

There are two types of dowel bars.

a. Stainless steel dowel bar.

b. Epoxy-coated dowel bar.

2. Purposes of Dowel Bar

The aim of dowel bar or steel is given below:

a. The aim of the dowel bar is to advance the performance of joints.

b. Dowel bars are kept for the aim of transferring load across concrete joints.

c. It is utilized to decrease corner cracking.

d. Dowel bars are given for the aim of decreasing the joint faulting

e. It is given for the aim of transferring the load from one member to another member such as one slab to another slab.

Normally, we left 50D in length, multiplying the diameter of the bar with 50 (50 x 16) 16 is the diameter of steel then the length of the dowels rebar is known which is 800mm.

| Read More: Size of Steel used in Construction |

3. Advantages of Dowel Bar

The advantages of dowel bar are listed below:

a. The dowel bar deflects the breakup of the concrete members because of the essential horizontal movement.

b. Dowel bar is used to extend the structure easily small drilling is required to insert the steel for the extension of the structure.

c. It advances the workability of structural member joints

d. It rises the initial cost of the project but reduces the life Cycle Cost.

e. Dowel bars rise the initial structural member’s life.

f. Dowel bar is utilized to rises the load-carrying capacity of the slab.

g. Dowel bar is used to decrease deflection and stress.

4. Disadvantages of Dowel Bar

a. Problem during installation.

b. Poorly compacted concrete around dowel bars.

| Read More: Flush Mortar Joint |

5. Length of Dowel Bar And Their Sizes

The length of dowel bar and sizes are provided in the table:

| S.No | Pavement thickness (in) | Min Dowel Length (in) | Max Dowel Spacing (in) | Dowel dia (in) | Dowel Type |

| 1 | Less than 8 | 16 | 12 | 0.75 | Steel Bar |

| 2 | 8 to 11 | 16 | 12 | 1 | Steel Bar |

| 3 | 12 to 15 | 20 | 15 | 1.25 | Steel Bar |

| 4 | 18 to 20 | 20 | 18 | 1.5 | Steel Bar |

| 5 | 21 to 25 | 24 | 18 | 2 | Steel Bar |

| 6 | Greater than 25 | 20 | 18 | 3 | Steel Bar |

Read More: Floor Space Index

Read More: Intake structure