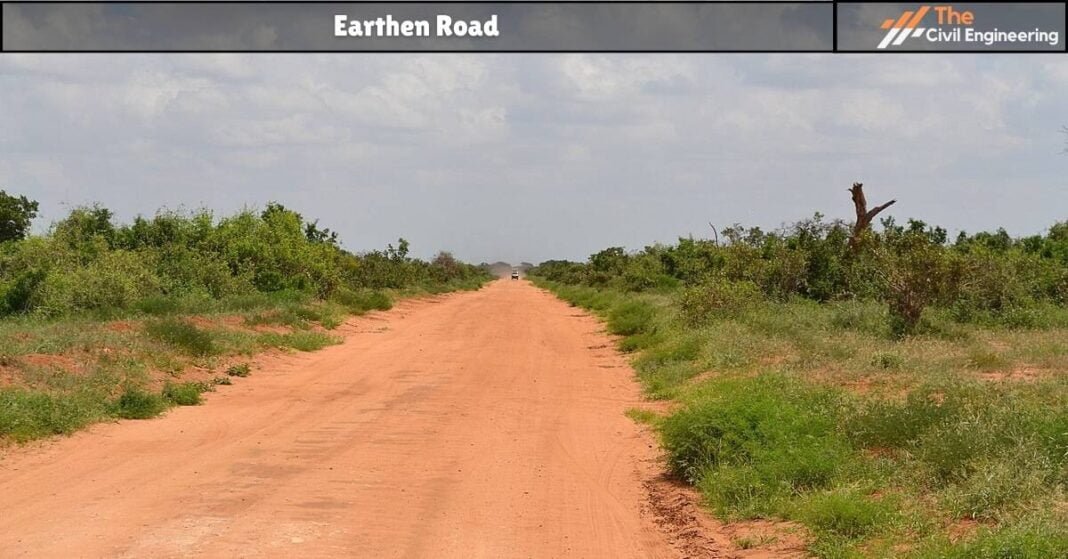

| Summary:If the pavement structure is constructed using the soil available at the site, it is called an earthen road. The soil used for the construction may be natural or stabilized. This road is mainly used in rural areas. This road is dusty, and ruts are formed quickly. There is a requirement for frequent maintenance (mainly after Monsoon). |

1. What is an Earthen Road?

Earthen Road is a low-cost road in which a pavement structure is constructed with the soil available at the site.

✓ It is also known as Earth Road.

✓ This road is commonly utilized for agricultural road networks, which is essential for transporting agricultural goods and commodities.

✓ This type of road is generally constructed in village or rural areas.

✓ The earthen road is the lowest form of pavement surface used and is considered the first stage in the development of road pavement construction.

✓ This type of road requires frequent maintenance to make it serviceable, i.e., mainly after the Monsoon.

2. How many types of Earthen Road are there?

There are 2 types of earthen roads

a. Ordinary Earthen Road

b. Stabilized Earthen Road

a. Ordinary Earthen Road

✓ The earthen road, whose foundation and the wearing surface consist of one or more compacted layers of natural soil along its Alignment, is an ordinary earthen road.

✓ Such a type of road surface is generally dusty, and ruts are formed quickly.

b. Stabilized Earthen Road

✓ Stabilized earthen road is an earthen road whose foundation and the wearing surface are constructed from one or more compacted layers of stabilized soil ( Stabilized with physical, chemical, or biological agents to increase strength and durability).

✓ It can carry greater traffic and load and provides better service than ordinary earthen roads.

3. What are the differences between Ordinary and Stabilized Earthen Roads?

| Feature | Ordinary Earth Road | Stabilized Earth Road |

|---|---|---|

| Foundation and wearing surface | Natural soil | Stabilized soil |

| Maintenance | Frequent | Less frequent |

| Durability | Less durable | More durable |

| Load-bearing capacity | Lower | Higher |

| Traffic suitability | Light traffic | Heavy traffic |

| Cost | Less expensive | More expensive |

| Suitability for weighty vehicles | Not suitable | Suitable |

| Dustiness | Dusty | Less dusty |

| Rut formation | More prone to ruts | Less prone to ruts |

4. Materials Required For Construction

✓ The material required for the earthen road is well-graded soil with aliquid limit of less than 35% and a plasticity index of 4-10%.

| Read Also: Casagrande Test for Liquid Limit of Soil |

5. Tools and Equipment Used In Construction

1. Spade

✓ It is used to dig or break soil lumps.

2. Shovel

✓ It is used for digging, lifting, and moving materials like soil, gravel, etc.

3. Wheel Barrow

✓ It is used to transport materials from one site point to another desired point.

4. Dozer

✓ It is used for excavation purposes ( i.e., in cutting and filling works).

5. Roller

✓ It is used for compacting the road surface.

6. What is the Construction Procedure for Earthen Road?

The construction procedure includes the following steps:

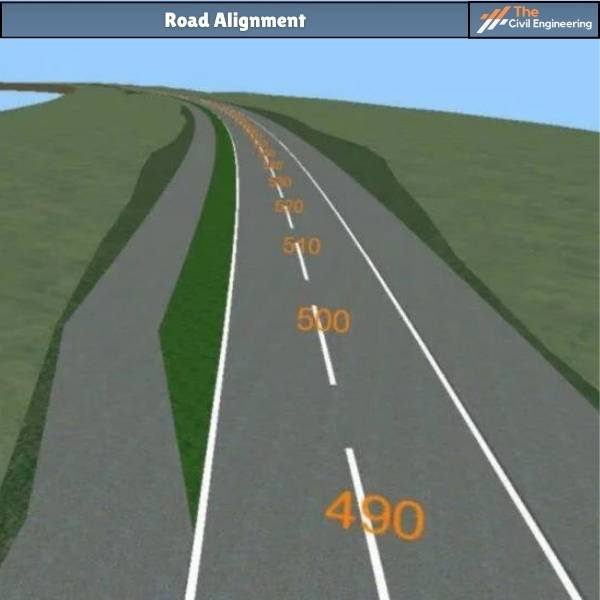

a. Locating Alignment

The road’s centerline and edges are marked with the help of a wooden peg.

The Alignment of the road is selected such that:

✔ It is short in length.

✔ It is easy to construct.

✔ It is safe for users ( Free from rockfalls & landslides ).

✔ It is economical.

| Read Also: Consolidation Test on Soil |

b. Soil Survey & Preparation of Sub-grades

A soil survey is carried out to determine the soil’s stability and approximate load-bearing capacity.

The level of compaction and the number of soil layers required for the subgrade preparation depend upon the soil’s bearing capacity.

Preparation of subgrade includes the following steps:-

✔ Clearing the Alignment: It is required to clear the road alignment from grasses and vegetal covers.

✔ Excavation or filling work up to the desired grade.

✔ Shaping the subgrade.

✔ Compacting the sub-grade. Depending on the soil’s nature, additional soil layers may be required.

c. Pavement Construction

✔ The borrowed soil is dumped on the prepared sub-grade and spread to achieve the desired cross slope (i.e., camber), and final compaction is done at OMC (Optimum Moisture Content) to get the required compaction grade.

✔ Thickness of the pavement layer is commonly 10 cm.

✔ Compaction work is then carried out with a slight application of water.

d. Opening to Traffic

✔ The compacted earthen road is allowed to dry for 1 to 3 days before traffic opens.

7. What are the advantages of Earthen Road?

1. It is the cheapest type of road and can be constructed on a low budget.

2. Earthen materials are easily available.

3. Local people and materials are utilized during the construction.

4. Can be blacktopped easily whenever required.

5. Can be constructed in less time ( i.e., Fast Construction).

8. What are the Disadvantages of Earthen Road?

1. Requires frequent maintenance ( mainly after heavy rainfall).

2. Dusty.

3. Can’t bear heavy loads.

4. Ruts are formed quickly.

| Read Also: Tension Test on Steel Rod |

9. FAQs

| Question | Answer |

| 1. Why is Earthen Road cheap? | Local labor and materials are utilized to construct this road.The soil available at the site is used to construct this road. |

| 2. Is this road used in developed countries? | Yes, in rural areas of developed countries, this road is used. |

| 3. How much does this road cost to build? | 20 to 25% of the budget for Flexible Pavement or 10 to 15% of the budget of Rigid Pavement. |

| 4. Are there only 2 types of earthen roads? | No, there is no relevant detail regarding how many earthen roads are there.We have written only 2 common types in this article. |

| 5. Can earthen roads be upgraded? | Yes, You can easily upgrade earthen roads to blacktop roads. |

Read More: Setting Time of Cement

Read More: Stripping Value Test on Aggregates