In this, we will discuss the initial and final setting time of cement.

1. Introduction

The aim of this test is to determine the initial and final setting time of cement.

The initial and final setting time of cement is calculated to provide enough time for different operations such as mixing, transportation, placing, and compaction of cement mortar or concrete.

The final setting time is calculated to know that after laying the mortar or concrete, the hardening must be rapid so that the structure may be utilized as quickly as possible. Both initial and final setting times of cement should be done with proper precaution.

1.1 Initial and Final Setting Time of Cement

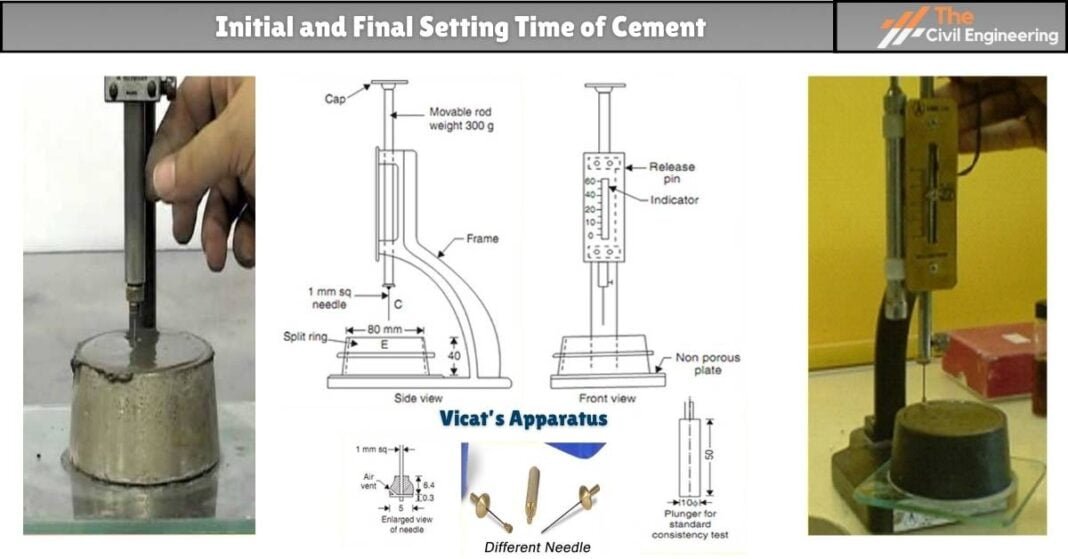

The cement paste is prepared ( As mentioned in the consistency test ) and is filled in the Vicat mold.

A round or square needle having a cross-sectional area of 1 mm² is fixed to the moving rod. The needle is then released quickly and it is permitted to penetrate the cement paste. The needle is then again taken out and dropped at a fresh place.

The procedure is to repeat at regular intervals till the paste stiffens sufficiently. for the needle to penetrate only to point above 5 mm from the bottom; at this stage, the initial set is said to have taken place.

The initial set is written as the time elapsed since the mixing water was added to the cement. This time should be about 30 minutes of ordinary cement.

1.1.1 Precautions

During the test, the temperature of water and cement paste should be kept within 27 ± 2°C and at an atmosphere of 90% relative humidity ( it is the ratio of the mass of water vapor present in a given volume of the atmosphere at a given temperature, to the mass of vapor required to saturate the same volume of air at the same temperature).

This test is done at a similar temperature and relative humidity as in the case of consistency.

1.2 Final setting Time

The cement paste is made as above steps and it is filled in the Vicat mold.

The needle having the annular collar 1mm square needle fixed with a metal fitting hollowed out. So, as to go from a circular cutting edge 5 mm diameter and fixed 0.5mm behind the top of the needle is jointed to the moving rod of the Vicat mold.

The final set is said to have taken place when the needle, gently lowered to the surface of the plate, makes an impression on it but the circular cutting edge fails to do so.

The final setting time is calculated from the moment when mixing water was added to the cement. This time must be nearly about 10 hours for ordinary cement.

This test is performed at the same temperature and relative humidity as in the case of the consistency test.

According to Indian standard specifications the setting times for ordinary, rapid hardening and low heat portland cement are:

Initial setting timeless than,

| Ordinary | Rapid Hardening | Low heat |

| 30 minutes | 30 minutes | 30 minutes |

final setting time more than,

| Ordinary | Rapid Hardening | Low heat |

| 10 hours | 10 hours | 10 hours |

It should be remembered that speed of setting and rapidity of hardening, that is gain of strength is entirely independent of another.

For instance, the prescribed setting times of rapid hardening cement are no different from those for Ordinary Portland cement, although two types of cement harden at different rates.

| Read More: Profometer Test |

| Read More: Stripping Value Test on Aggregates |