THE LOS ANGELES ABRASION TEST IS CARRIED OUT ON AGGREGATES TO DETERMINE THE HARDNESS AND ABRASION CHARACTERISTICS, I.E., ABILITY TO RESIST DEGRADATION DUE TO IMPOSED WHEEL LOAD.

✔ The principle of this test is to determine the percentage of wear due to deliberate rubbing action between aggregates.

✔ Steel balls are used as an abrasive charge to create the test’s rubbing action.

✔ The percentage wear of the aggregates due to rubbing with steel balls is taken as the abrasion value.

1. Importance of the Los Angeles Abrasion Test

a. It helps to determine aggregates’ strength, toughness, relative quality, abrasion characteristics, and physical behavior.

b. It gives the idea to improve aggregate properties to bear the load and be workable, reliable, and durable for stable and stiff structures.

c. This test indicates that the more abrasive materials are relatively less hard and can be easily damaged.

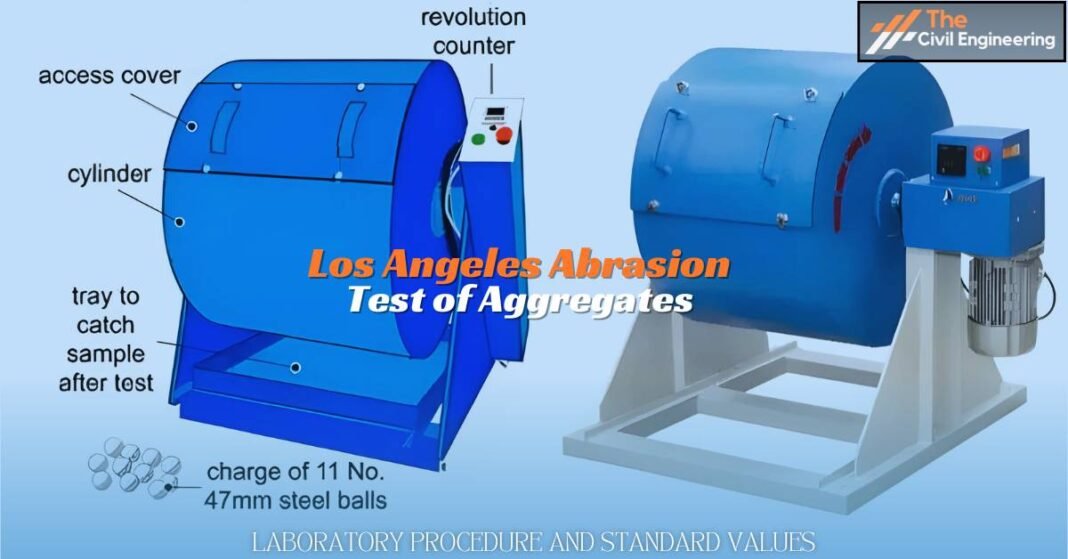

2. Apparatus Required

a. Weighing Balance

b. Sieves as per gradation of aggregate 80 mm, 63 mm, 50 mm, 40 mm, 25 mm, 20 mm, 12.5 mm, 10 mm, 6.3 mm, 4.75 mm, and 1.7 mm.

c. Abrasion testing machine with an inside diameter of 70 cm and inside length of 50 cm.

d. Steel balls (abrasive charge) of diameter 48mm and weighing between 390 gm to 445gm.

3. Selection of Abrasive Charge for Los Angeles Abrasion Test

| Grading | No. of Steel balls | Weight of charge in gm. |

| A | 12 | 5000 ± 25 |

| B | 11 | 4584 ±25 |

| C | 8 | 3330 ± 20 |

| D | 6 | 2500 ± 15 |

| E | 12 | 5000 ± 25 |

| F | 12 | 5000 ± 25 |

| G | 12 | 5000 ± 25 |

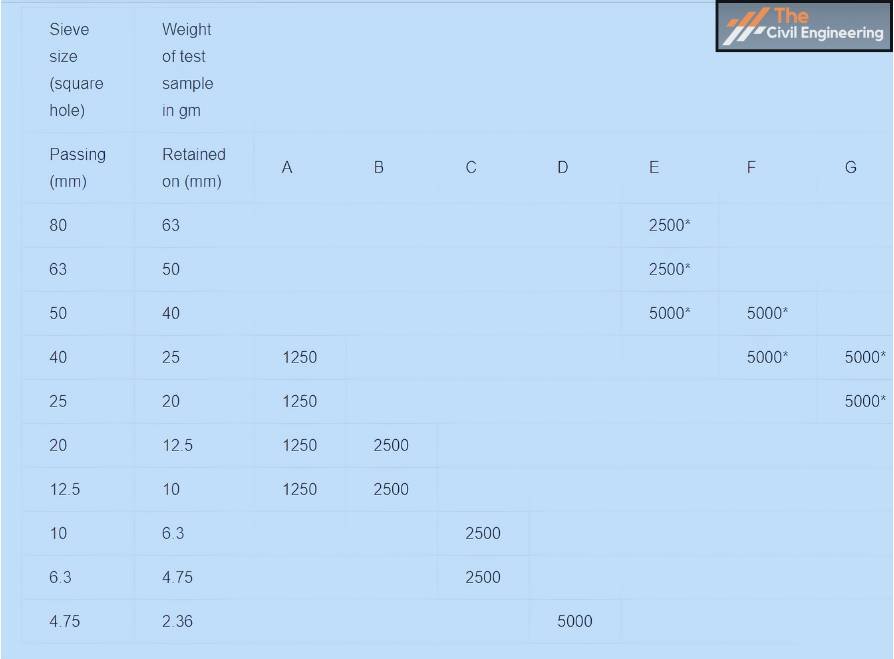

4. Grading of Test Samples

*Tolerance of ± 12 %permitted

5. Procedures in Los Angeles Abrasion Test

1. The test sample must contain clean well-graded aggregates that have been oven-dried at a temperature ranging from 105º to 110º Celsius.

2. The aggregates and abrasive charges are placed in the Los Angeles Abrasion Testing Machine.

3. The machine is then rotated at a 20 to 33 rev/min speed.

4. The machine shall be driven to maintain a uniform peripheral speed.

5. After the completion of the test, the coarse aggregate is taken out and passed through sieves.

6. The aggregates coarser than 1.7 mm IS sieve are then separated.

7. The retained aggregates are then oven-dried at 105 – 110ºC and finally weighed.

8. The Los Angeles Abrasion Value is then calculated using the following formula:

Abrasion value = [ (WA-WB) / WA ] * 100

Where,

WA= weight in gm of oven-dried sample

WB= weight in gm of the fraction of aggregate retained on 1.7 mm sieve after oven-dried

6. Suitable Abrasion Value for Pavements

| Sl. No. | Type of Pavement | Max. permissible abrasion value in % |

| 1 | Water-bound macadam sub-base course | 60 |

| 2 | WBM base course with the bituminous surfacing | 50 |

| 3 | Bituminous bound macadam | 50 |

| 4 | WBM surfacing course | 40 |

| 5 | Bituminous penetration macadam | 40 |

| 6 | Bituminous surface dressing, cement concrete surface course | 35 |

| 7 | Bituminous concrete surface course | 30 |

7. Precautions in Los Angeles Abrasion Test

a. While performing the LA abrasion test, it should be noted that the abrasion machine is being rotated at about (20-33) rpm.

b. Test should be performed at room temperature to avoid humidity causing errors.

Read Also: CBR Test