Milling may be defined as a process done with a machine in which the cutters rotate to separate the material from the workpiece available in the direction of the angle with the tool axis.

With the support of a Milling machine, we can do various operations and functions progressing from tiny objects to huge ones.

It is the most commonly utilized manufacturing mechanism in machinery shops and industries to produce high-precision products and parts in various shapes and sizes.

1. Milling Machine

It can be referred to as multitasking machines (MTMs) which are multi-purpose machines that are efficient in milling and turning the materials as well.

The milling machine contains the cutter fitted on it which is utilized in removing the material from the surface of the workpiece. When the material cools down then it is separated from the milling machine.

a. CNC Milling Machine

CNC Milling Machines refer to machine-operated cutting tools that are programmed and controlled by Computer Numerical Control (CNC) systems to exactly separate materials from a workpiece.

The last result of the machining process is a particular part or product that is made by utilizing Computer-Aided Design (CAD) software.

2. Milling Process

The milling machine contains the following various processes of cutting:

a. Milling Cutters

There are various cutting tools utilized in the milling process.

The milling cutter’s end mills have better-cutting surfaces on their edge surfaces so that they can be kept onto the workpiece by drilling.

These also have long cutting surfaces on each side for the aim of peripheral milling. The milling cutters contain tiny cutters at the edge corners.

The cutters are prepared from highly resistant materials that are durable and emit less friction.

b. Surface Finish

The material is kept through the cutting area of the milling machine to achieve uniform intervals.

The side cutters contain uniform ridges on them.

The distance between the ridges relies on the feed rate, the diameter of the cutter, and the number of cutting surfaces.

These can be notable differences in the height of the surfaces.

c. Gang Milling

This means that more than two milling cutters are involved in a setup like horizontal milling.

All the cutters utilize a uniform operation or it can also be done that the cutter may act various works. This is very vital work for preparing duplicate parts.

| Read Also: Construction Tools List |

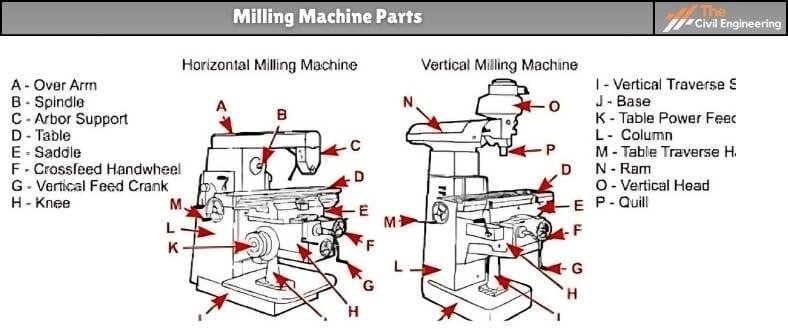

3. Milling Machine Parts

It has the following parts:

a. Base

b. Column

c. Knee

d. Saddle

e. Table

f. Over-Arm

g. Spindle or Arbor

h. Arbor supports

i. Ram

j. Milling Head

4. Types of Milling Machines

There are the vertical mill and the horizontal mill.

a. Vertical Milling Machines

The vertical mill contains a vertically managed spindle axis and rotates by remaining at a similar axis.

The spindle can also be increased and can do various functions such as drilling and cutting. The vertical mills contain two further categories as well: turret mill and bed mill.

The turret mill contains a table that progresses perpendicularly and parallels the spindle axis in order to chop the material. The spindle is, however, stationary. The two cutting methods can be utilized with this by progressing the knee and by decreasing or increasing the quill.

The other mill is known as the bed mill in which the table progresses perpendicular to the axis of the spindle and the spindle progresses parallel to its axis.

b. Horizontal Milling Machines

The horizontal mill is the same as the cutter but their cutters are kept on a horizontal arbor.

The horizontal mills contain rotary tables that support milling at various angles.

These tables are called universal tables.

Apart from this, all the tools that are utilized in a vertical mill can also be utilized in a horizontal mill.

5. Use of a Milling Machine

The different uses of milling machines are as follows:

a. It is used for machining helical surfaces of different cross-sections and more.

b. It is used for machining flat surfaces, Slotting, and Contoured surfaces.

c. It is used for preparing complex and irregular areas, revolution surfaces, Gear cutting, and machining external and internal threads.

| Note: In the food industry, flour mill machines are used for grinding grains, spices, herbs, and other materials too. |

6. Advantages

The advantages of milling machine are as follows:

a. It provides high speed.

b. It gives a better surface finish.

c. It increases productivity.

d. It has high accuracy.

| Read Also: Tunnel Boring Machine |

7. Disadvantage

a. Expensive to buy.

b. Heavy to transport

c. Skilled manpower is needed.

8. FAQ

1. What is Milling Machine?

The multi-purpose machines are efficient in milling and turning the materials as well.

2. What does a milling machine do?

Milling machines are used in milling and turning the materials as well.

3. What is a milling machine used for?

Milling Machine is utilized for machining flat surfaces, Slotting, and Contoured surfaces.

9. References1. Content Filter & Authenticity Checking Team, The Civil Engineering (Our team checks every content & detail to maintain quality.) |

Read Also: Cinder Block

Read Also: Types of Concrete Admixtures