A parapet wall is a dwarf or low wall that is constructed along the edge of the terrace, roof, balcony, walkway, passage, etc.

In other words,

The vertical extension of the wall at the edge of the roof, balcony, terrace, and walkway thereby creating a barrier is known as the parapet wall.

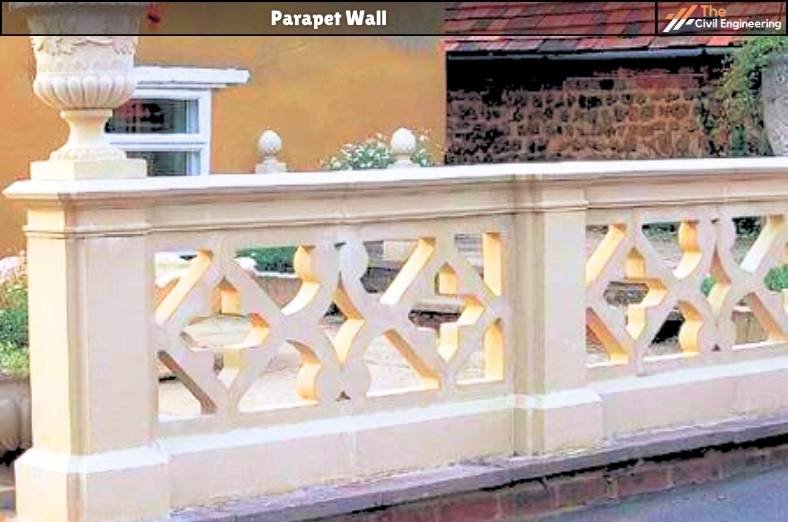

Fig: Parapet wall

It provides a significant degree of protection to the roofs, balconies, gutters, and walkways of houses, churches, monuments, commercial and other similar buildings.

Such a wall can be made from various materials such as the reinforced cement concrete, aluminum, glass, steel, masonry, etc.

It also permits the use of roof space more effectively and safely.

It has a long known history in the field of architecture and is still used extensively.

In ancient times, it was mostly used as a protective wall against ground attacks by the military forces.

It is also used as protection against fire hazards. So, it is also commonly referred to as the firewall.

For architectural and aesthetic purposes, most of the parapet walls are designed with trefoils and circles.

It also prevents accidents like falling from height.

It is also used to protect the entire roofing system against upward wind forces.

1. Major Uses of Parapet Wall

a. To increase the aesthetic appearance of the structure.

b. To protect ( or hide) the machinery and equipment kept on the rooftop of the structure such as units of A/ C.

c. To provide safety for humans from falling when they are on the roofs or terraces.

d. To prevent the vehicles from falling off a bridge.

e. To prevent the dust from entering into the rooftop.

f. To serve as a protective measure in military areas. Usually, perforated parapet walls are used in the military.

g. To eliminate wind load acting on the rooftop to a certain level.

h. To protect against fire because it also acts as a firewall.

2. Considerations During the Construction of Parapet Wall

Some things to consider during the construction of the parapet are:

a. Minimum height required for the parapet wall is 2.5 feet from the roof surface. ( Standard height of the parapet is 3 feet. Parapet wall should not cross 4 feet in any case.)

b. Minimum thickness required for the parapet wall is 4 inches. (Standard thickness of the parapet is 9 inches.)

c. The parapet wall should be plastered from both sides to eliminate the problem of dampness.

d. Joint between the roof and parapet should be sealed properly.

3. Types of Parapet Wall

1. Based on Appearance

According to the appearance of the parapet wall, it can be classified into four major categories naming plain, embattled, perforated, and paneled parapet wall.

a. Plain Parapet Wall

~ It is an extension of the vertical portion of the wall at the edge of the roof.

~ The primary purpose served by the plain parapet wall is the safety purpose.

~ The plain parapet is relatively easy to construct and requires low maintenance.

~ This parapet wall is not aesthetically pleasing i.e. dull in appearance.

~ Some features are:

a. Easy to construct and maintain.

b. Economical

c. Serves for both safety and privacy.

Fig: Plain Parapet Wall

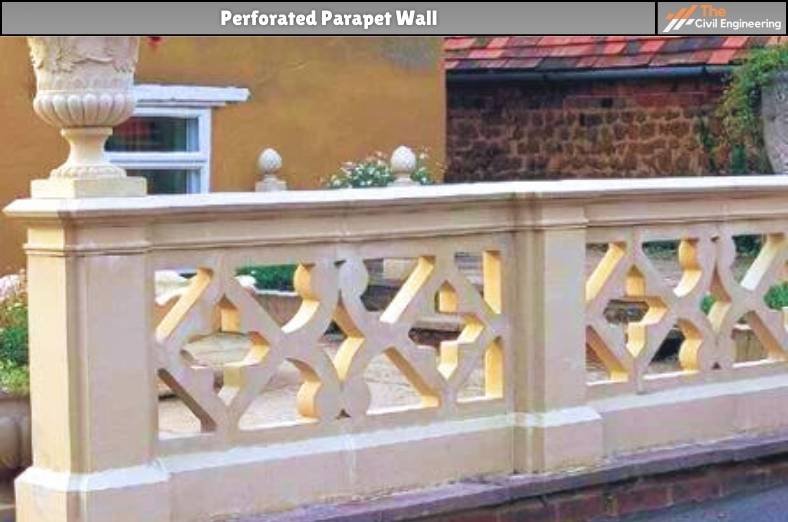

b. Perforated Parapet Wall

~ Like the plain parapet wall, it also comprises an extension of the wall but the extended portion of this wall is perforated with differently sized openings.

~ It is aesthetically appealing in nature.

~ Various types of designs of perforations can be used for this purpose.

~ Common types of perforation design used are circles, flower shapes, trefoils, etc.

Fig: Perforated Parapet Wall

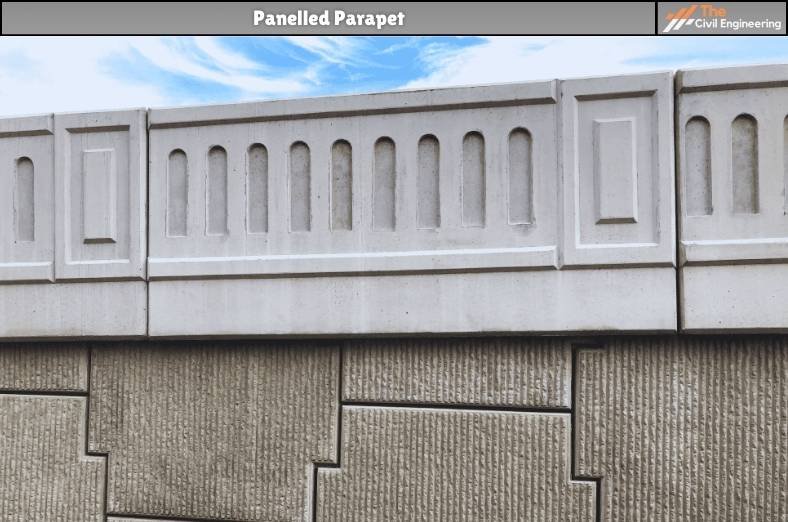

c. Panelled Parapet Wall

~ It is also similar to the plain parapet wall. The major difference between the walls is that the paneled wall is provided with a series of panels on the outer side.

~ The panels attached may be either oblong or square.

~ It provides a very pleasing aesthetic appearance to the entire structure. This is also comparatively cheaper and is very easy to construct. Due to this, it is extensively used all over the world.

Fig: Panelled Parapet

d. Embattled Parapet Wall

~ It is the ancient type of parapet wall used extensively in pre-historical times.

~ It was highly used in structures like castles, forts, etc.

~ In such type of parapet wall, a series of alternate high and low perforations are provided in the parapet.

~ The main reason for providing such perforations was to allow the arrow shooters to shoot the arrows through the perforations thereby defending the structure from external attacks.

~ It is aesthetically pleasing in nature. Due to this, it is still used nowadays to enhance the aesthetic appearance of the structures.

Fig: Embattled Parapet

2. Based on Configuration and Shape

According to the configuration and the shape of the parapet wall, it can be classified into four main types naming sloped, stepped, flat, and curved parapet wall. These types of parapet walls are further explained below.

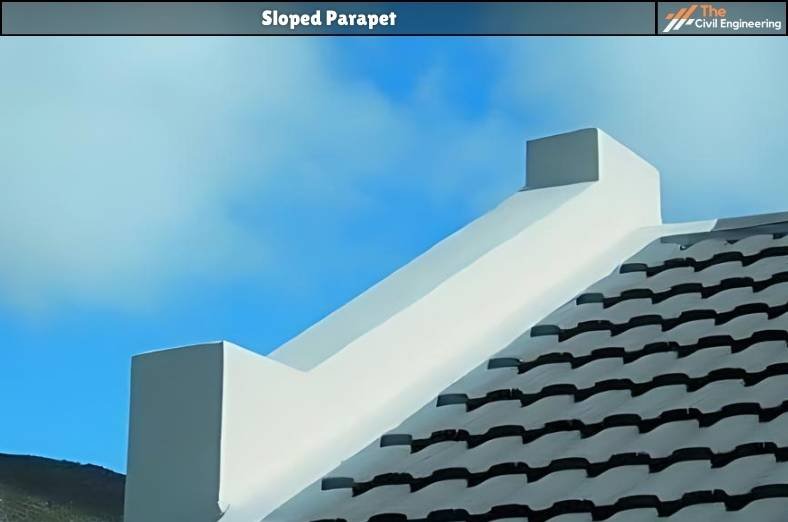

a. Sloped Parapet Wall

~ It is provided for sloped roof structures such as industrial structures, trussed structures, etc.

Fig: Sloped Parapet

b. Flat Parapet Wall

~ As the name itself implies; the flat parapet wall is used in the flat roofs.

Fig: Flat Parapet

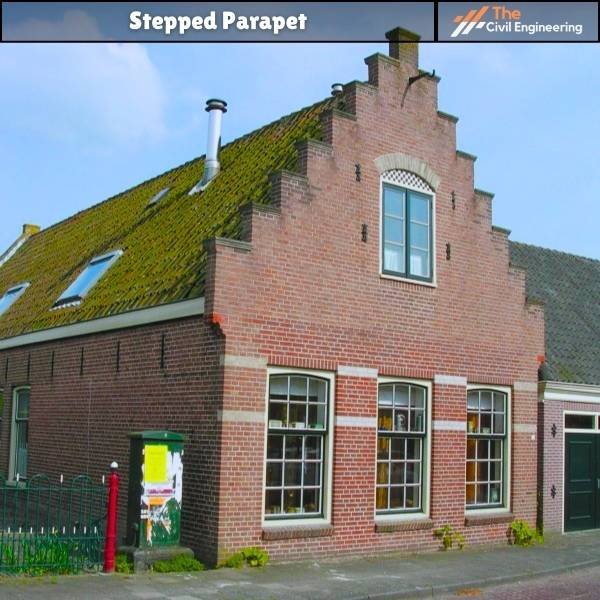

c. Stepped Parapet Wall

~ It is constructed similar to the design of a staircase.

~ This parapet is extensively used for the inclined type of roof structures.

Fig: Stepped Parapet

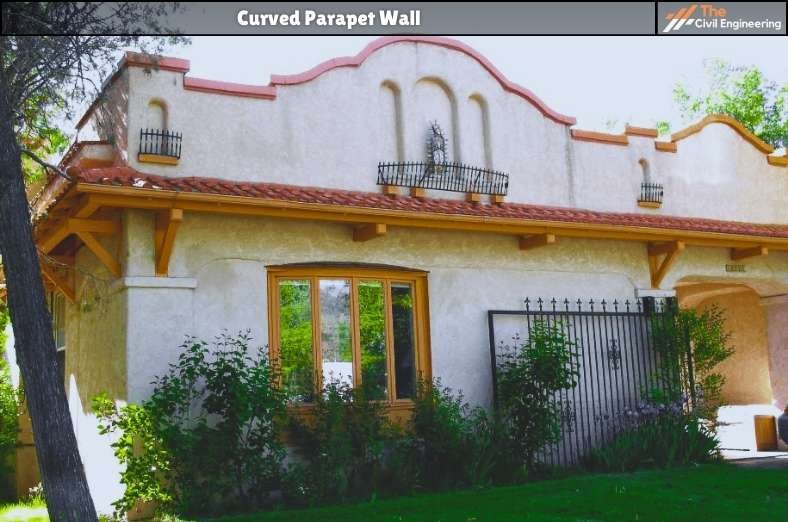

d. Curved Parapet Wall

~ It is the parapet wall that resembles a curve in appearance.

~ It is commonly referred to as the arched parapet wall.

~ This type of parapet is aesthetically pleasing in nature.

~ It is suitable for both flat roofs and inclined roofs.

Fig: Curved Parapet

3. Miscellaneous Types

In recent days, various new designs and types of parapet walls are emerging for improving the safety aspects and appearance of the conventional parapet wall.

Some of the recent types of parapet walls include fiber-glass parapets, parapets with steel railings, etc.

The combination of two or more parapet walls is also being used these days. Such a parapet wall is referred to as the composite parapet wall. For example, a perforated parapet wall provided with glass and steel railings is used to enhance the aesthetic appearance of the buildings.

Fig: Composite parapet

4. Advantages of Parapet Wall

Some advantages of this wall are:

a. Prevents accidents like height fall.

b. Prevents spreading of fire from one section to another.

c. Protection of roofs against the upward wind forces.

d. Provides aesthetic beauty and unique looking.

5. Disadvantages of Parapet Wall

Some disadvantages of this wall are:

a. If caping is not applied correctly between the joint of roof and parapet; leakage may occur.

b. Requirement of a high level of expertise for beautiful designs.

6. Codal Provisions for Parapet Wall Construction ( IBC)

IBC Section 705.11 defines the requirements for parapet.

As a default, the code requires that parapets should be installed on all exterior walls of a building. However, there are several exceptions to this, notably when one of the following conditions exists:

a. The exterior wall does not require a fire-resistance rating based solely on fire separation distance per IBC Table 602 (e.g., most multi-family, wood-frame projects would need a fire separation distance of 30 ft or more; Type VB construction with multi-family occupancies would need a fire separation distance of 10 ft or more)

b. The building area is less than 1,000 sq. ft on any given floor.

c. The entire roof construction is of noncombustible materials or at least 2-hour fire-resistance-rated construction (not common on most wood-frame projects).

d. The building has 1-hour fire-resistance-rated exterior walls that terminate at the underside of the roof sheathing, provided that:

~ Roof construction that spans parallel to the exterior wall is not less than 1-hour rated for 4 ft from the interior side of the wall for Group R/U; 10 ft for other occupancies, or

~ Roof construction that spans perpendicular to the exterior wall is not less than 1-hour rated for its entire span

~ For either of the above cases, openings in the roof are not within 5 ft of the exterior wall for Group R/U or within 10 ft for other occupancies, and

~ The entire building has a class B roof covering

e. For Group R-2 or R-3 occupancies, the building is of Type III, IV, or V construction and has a class C roof covering, provided that:

- The roof sheathing or deck is non-combustible or fire-retardant-treated wood for a minimum of 4 ft from the exterior wall, or

- 5/8″ Type X gypsum board is installed directly to the underside of the roof sheathing or deck for a minimum distance of 4 ft from the exterior wall

f. IBC Section 705.8 allows the exterior wall to have 25% or more of its openings unprotected as a function of fire separation distance.

g. If none of the exceptions applies and a parapet is required, IBC 705.11.1 lists the construction requirements as follows.

705.11.1 Parapet wall construction

Parapets shall have the same fire-resistance rating as that required for the supporting wall, and on any side adjacent to a roof surface, shall have noncombustible faces for the uppermost 18 inches (457 mm), including counter flashing and coping materials.

The height of the parapet shall be not less than 30 inches (762 mm) above the point where the roof surface and the wall intersect. Where the roof slopes toward a parapet at a slope greater than 2 units vertical in 12 units horizontal (16.7 percent slope), the parapet shall extend to the same height as any portion of the roof within a fire separation distance where protection of wall openings is required, but in no case shall the height be less than 30 inches (762 mm).

This section notes that the parapet shall have the same fire resistance as the exterior wall below it. Although it is not stated, it is common to interpret this as applying to fire rating requirements for both the inside and outside faces of the wall. For Type V construction, IBC Table 601 requires a 1-hour rating for exterior bearing walls, while no rating is required for non-bearing walls.

Type III construction requires a 2-hour rating for exterior bearing walls. Fire separation distance should also be checked to determine the most restrictive requirements between Tables 601 and 602.

Note that IBC 705.5 only requires exterior walls to be rated from both faces when the fire separation distance is 10 ft or less. Otherwise, the required rating only applies to the inside face of the exterior wall.

The minimum height of a parapet wall above the roof surface is 30 inches. However, when a roof slopes down toward an exterior wall and parapet with a slope greater than 2:12, further analysis is required to determine if a taller parapet is necessary.

In Type III construction, exterior walls are required to be noncombustible or framed with fire-retardant-treated wood (FRTW). Under these circumstances, another common question is whether parapets on Type III buildings need to be framed with FRTW. Although IBC 705.11.1 doesn’t specify the requirements for parapet construction materials, some have interpreted that code intent would imply that the use of FRTW is necessary for parapet wall construction; others have not. This is a subject that should be discussed with the Authority Having Jurisdiction regarding their interpretation and requirements.

Under certain circumstances, parapets may not be required by code (using one of the exceptions noted above) but are still installed on a building to serve aesthetic functions.

In this case, a common question is whether or not the parapet needs to follow the fire-resistance rating and construction requirements of IBC 705.11. For this scenario, some designers have successfully designed and constructed parapets without a fire-resistance rating (even when the exterior wall below requires one) by using the rationale that the parapet is similar to a roof member/roof extension or an exterior wall projection as opposed to an exterior wall member. This is based on the fact that the parapet is not required by code and, therefore, is not required to provide fire containment.

| Read More: Shoring |

| Read More: Surveyor Compass |