1. Introduction

Generally, the setting time of cement can be divided into the initial setting time and the final setting time. In very simple terms, the initial setting time may be understood as the time when the cement paste first starts to harden.

On the other hand, the final setting time may be understood as the time when the cement paste hardens to a state such that a 1mm needle can make an impression on the paste of cement, but a 5mm needle does not leave behind an impression.

The determination of the setting time of cement is an important parameter for ascertaining the quality and suitability of concrete in a particular type of construction.

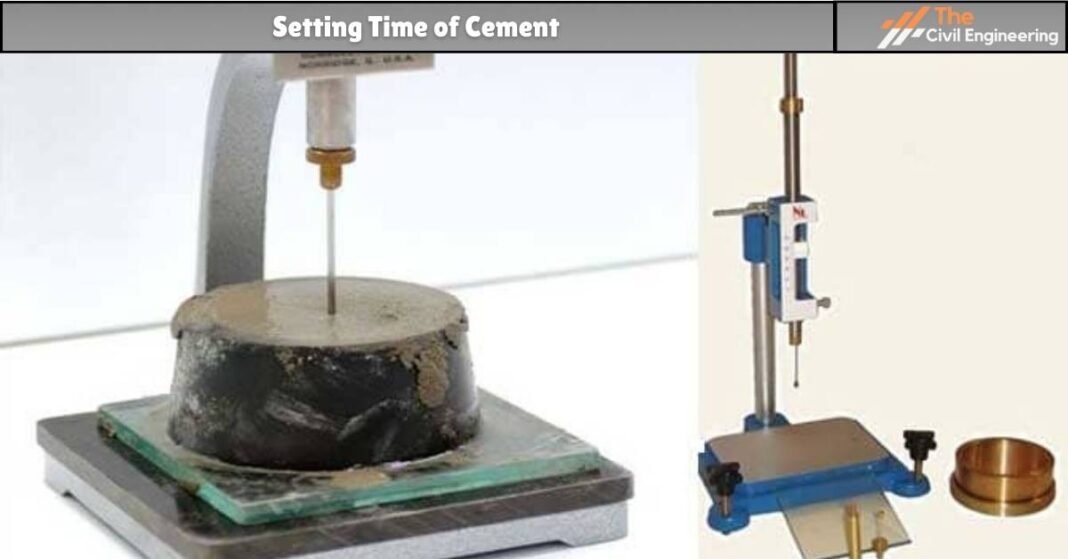

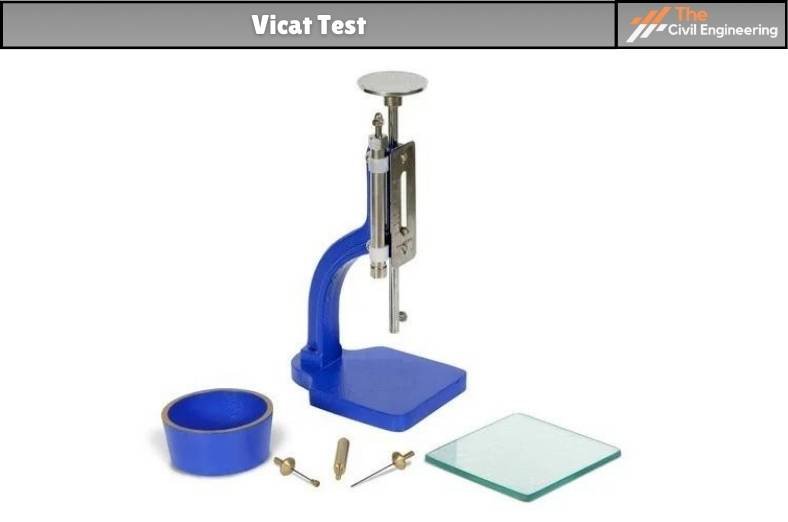

Setting time is tested by using the Vicat Test.

In other words, initial setting time refers to the time when the paste starts to lose its plasticity while the final setting time is the time when the paste completely loses its plasticity.

During the final setting time of cement, the primary chemical reaction between the cement and water is almost completed.

2. Significance of Setting Time of Cement

a. The initial setting time of concrete is required for transportation, placing and compaction of cement concrete.

b. The initial setting time is also necessary for delaying the process of hydration or hardening.

c. The final setting time facilitates the safe removal of scaffolding as well as formworks.

3. Apparatus Required

a. Vicat’s Apparatus

b. Measuring Cylinder

c. Stopwatch

d. Balance

e. Enamel Tray

f. Glass Plate

g. Trowel

4. Lab Procedure

The test procedure for the determination of setting time involves the following series of steps:

I. Initial Setting Time Test

~ About 400 grams of the cement is taken, and a well-mixed cement paste is prepared.

~ The gauge time is kept between 3 to 5 minutes, and the stopwatch is started exactly when water is added to the cement. This time is recorded as T1.

~ First, the sample of the concrete is filled in the mould of the Vicat’s apparatus and resting on the non-porous plate under the rod bearing needle.

~ The needle is then gently lowered until it comes in contact with the surface of the test mould thereby allowing the needle to penetrate the test block.

~ It can be seen that at first the needle completely pierces the mould. The process is repeatedly performed, and the needle is released after every two minutes till the needle cannot further penetrate the block for about 5mm from the bottom of the mould.

~ The time at this instant is noted as T2.

II. Final Setting Time Test

~ To determine the final setting time of cement, the needle is replaced with a needle with an annular attachment.

~ The cement is finally considered to be set when the needle lowered on the surface of the test mould makes an impression, but the attachment does not make any impression. This time is noted as T3.

5. Calculations

The initial and final setting time is then computed as follows:

Initial Setting Time = T2 – T1

Final Setting Time = T3 – T1

Where,

T1 = Time at which water is first added to the cement.

T2 = Time when the needle fails to penetrate 5mm to 7mm from the bottom of the mould.

T3 = Time when the needle makes an impression, but the attachment does not make any impression.

6. Result

Initial setting time of cement………..

Final setting time of cement……….

7. Precautions

a. Each time needle must be cleaned properly before its use.

b. The mould should be shifted after recording the penetration of the needle so that the penetration of the needle does not coincide in the same place.

c. The temperature must be 20±2°C, and the minimum relative humidity must be 65% while mixing is done, and the cement paste should be stored at 20±1°C and a maximum relative humidity of 90%.

| Read Also: Tests on Rock |