Timber is defined as the structural wood that has been used in construction or other engineering fields from historical times.

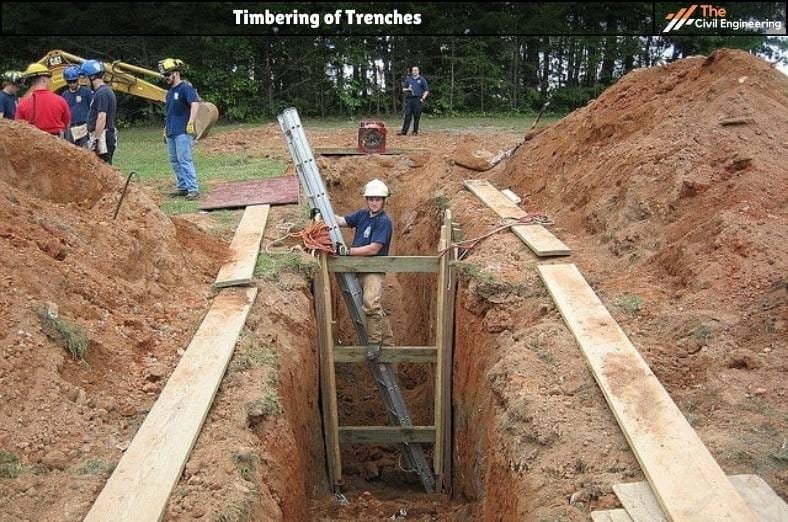

When the depth of the trench is large, or when the sub-soil is loose, the sides of the trench may cave in.

The problem can be solved by adopting a suitable method of timbering. Timbering of trenches, sometimes also known as shoring consists of providing timber planks or boards and struts to give temporary support to the sides of the trench.

1. Timbering of Trenches

Timbering of trenches can be done with the help of the following methods:

a. Stay bracing.

b. Box sheeting

c. Vertical sheeting

d. Runner system

e. Sheet piling.

a. Stay bracing

This method is used for supporting the sides of a bench excavated in fairly firm soil when the depth of excavation does not exceed about 2 meters. The method consists of placing vertical sheets (called sheathing) or polling boards opposite each other against the two walls of the trench and holding them in position by one or two rows of struts. The sheets are placed at an interval of 2 to 4 meters and generally, they extend to the full height of the trench.

The polling boards may have a width of about 200 mm and a thickness of 40 to 50 mm. The struts may have a size of 100 x 100 mm for trenches up to 2 m in width and a trench up to 4 m in width.

b. Box Sheeting

This method is adopted in loose soils when the depth of excavation does not exceed 4 meters.

The box-like structure consists of vertical sheets placed very near to each other (sometimes touching each other) and keeping them in position by longitudinal rows (usually two) of wales. Struts are then provided across Wales.

Another system of box sheeting is adopted for very loose soils. In this system, the sheeting is provided longitudinally, and they are supported by vertical wales and horizontal struts. If the height is more, braces are also provided along with struts.

c. Vertical sheeting

This system is adopted for deep trenches (up to 10 m depth) in soft ground. The method is similar to box sheeting except that the excavation is carried out in stages and at the end of the stage, an offset is provided so that the width of the trench goes on decreasing as the depth increases.

Each stage is limited to about 3 m in height and the offset may vary from 25 to 50 cm per stage. For each stage, separate vertical sheeting, supported by horizontal wailings and struts is provided.

| Read More: Sanitary Fittings |

| Read More: Systems of Plumbing |

d. Runner System

This system is used in extremely loose and soft ground, which needs immediate support as excavation progresses. The system is similar to the vertical sheeting of the box system, except that in the place of vertical sheeting, runners, made of long thick wooden sheets or planks with an iron shoe at the ends, are provided. Wales and struts are provided as usual.

These runners are driven about 30 cm in advance of the progress of the work, by hammering.

e. Sheet Piling

This method is adopted when

(i) the soil to be excavated is soft or loose

(ii) the depth of excavation is large

(iii) the width of the trench is also large and

(iv) There is subsoil water.

Sheet piles are designed to resist lateral earth pressure. These are driven in the ground by mechanical means (pile driving equipment). They can be used for excavating to a very large depth.

This was for the Timbering of Trenches.

2. References1. Content Filter & Authenticity Checking Team, The Civil Engineering (Our team checks every content & detail to maintain quality.) |

Read More: Sewage

Read More: Standard Proctor Test of Soil