1. Introduction

The rebound hammer test on concrete is the type of non-destructive test of concrete. In simple terms, a non-destructive test on concrete is employed to measure the strength of the concrete without actually destroying the structure.

The primary objective of such a test is to evaluate the strength and durability of the existing concrete structure as well as for the identification of cracks and defects. One such type of the non-destructive test on concrete structures is the Rebound Hammer Test.

The Rebound Hammer test can be defined as the test that is conducted to evaluate the compressive strength of the existing concrete structure particularly for the repair of the RCC structures.

The test is carried out utilizing a simple device which is known as the Rebound Hammer.

The hammer commonly used for such test is the Schmidt Hammer as invented by a Swiss Engineer named Ernst Schmidt.

2. Applications of Rebound Hammer Test

The main applications of the rebound hammer test on concrete can be listed as follows:

1. It is used extensively for the evaluation of the hardness of concrete. Thus, the quality of the concrete surface can be assessed.

2. It is used to evaluate the compressive strength of concrete structures without destroying the structure.

3. It is used to find the exact location of weaker portions of concrete thereby facilitating the repair works.

3. General Test Procedure of Rebound Hammer Test

The general test procedure of the rebound hammer test has been described below.

a. Theory

The basic principle of the rebound hammer test is that the rebound of an elastic mass mainly depends upon the hardness of the surface of concrete against which the mass strikes.

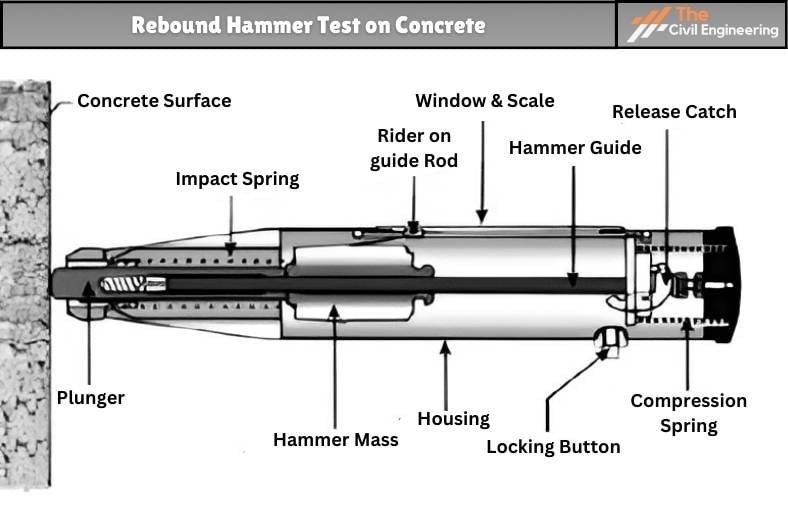

In actual practice, when the plunger of the hammer is pressed against the concrete surface, the spring controlled mass of the hammer undergoes rebound.

The measure or the amount of this rebound depends upon the hardness of the concrete surface.

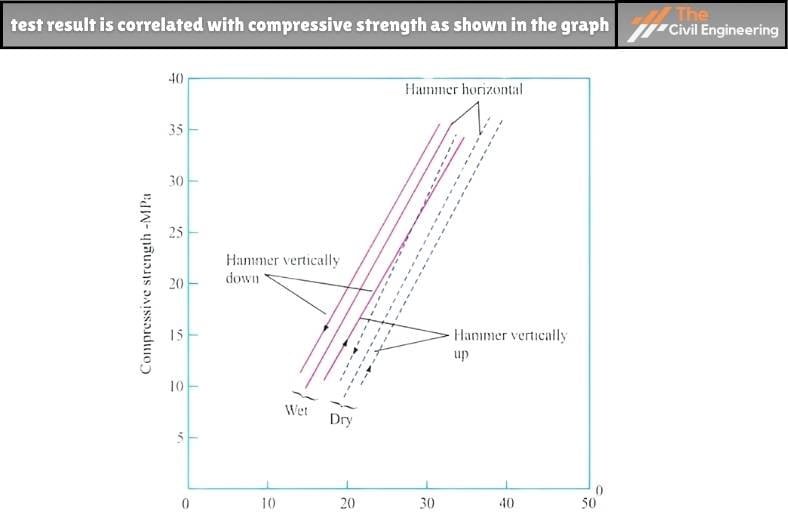

Hence, the obtained rebound hammer reading is correlated with the compressive strength of the concrete.

Rbound Number or Rebound Index is thus the rebound value that is read along the graduated scale.

b. Apparatus Required

Rebound Hammer

The test procedure includes the following series of steps:

The test procedure includes the following series of steps:

1. The rebound hammer is first calibrated. The calibration is done by testing the hammer against an anvil that is made up of steel whose Brinell hardness number is 5000 N/mm².

2. The concrete surface must be cleaned and well dried.

3. Then, the rebound hammer is held perpendicular to the surface of the concrete. The hammer may also be held vertically or horizontally.

4. The reading is then noted and the test result is correlated with compressive strength as shown in the graph.

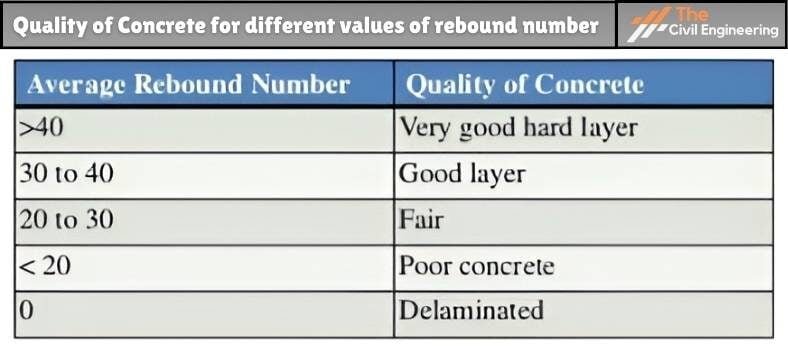

Table.1. Quality of Concrete for different values of rebound number

4. Advantages of Rebound Hammer Test

Some of the advantages of the rebound hammer test can be listed as follows:

1. The equipment required is simple and easy to use.

2. The test procedure is also simple and can be completed within a short period.

3. It is an economical test.

5. Disadvantages of Rebound Hammer Test

Some of the disadvantages of the rebound hammer test can be listed as follows:

1. The concrete surface to be tested must be smooth.

2. The test result varies significantly with the age of the concrete.

3. The results are obtained based on a local point.

| Read More: In-Situ Dry Density By Sand Replacement Method |

| Read More: Core Cutter Method |