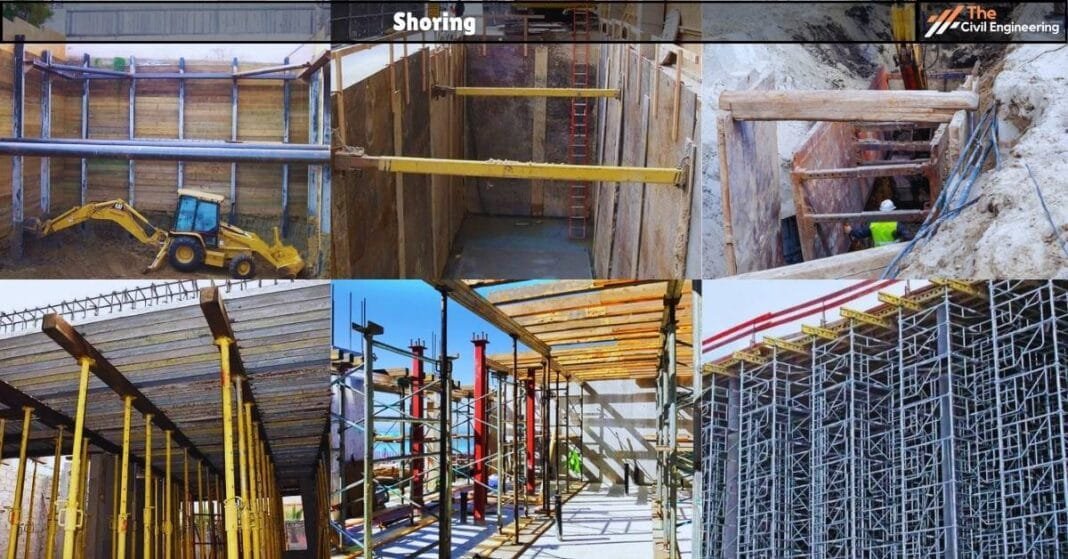

Shoring is a temporary structure constructed to provide support to an unsafe structure.

It provides lateral support to any unsafe structure.

The props that provide such support are commonly called the shores.

Shoring may be horizontal, vertical, or even inclined.

1. Conditions to Employ Shoring

1. When the walls of a structure crack due to unequal or varied settlement of the foundation.

2. When the walls bulge out of the structure.

3. When repair and maintenance works have to be done.

4. When an adjacent structure is to be demolished.

2. Primary Objectives

1. To provide support and stability to unsafe structures prone to structural instability and collapse due to bad workmanship, unequal settlement of the foundation, or other similar reasons.

2. To support structures when specific alterations (additions or omissions) are necessary in the structure, such as the underpinning of the foundations, demolishing of adjacent buildings, re-modeling of the walls, etc.

3. Types of Shoring

The types of Shoring are as follows:

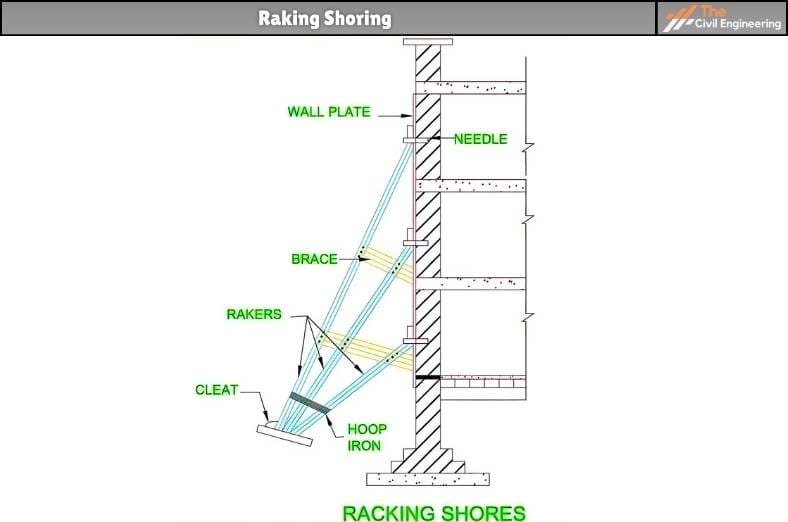

a. Raking Shoring

Raking Shoring is also called inclined Shoring.

It can be defined as the Shoring in which the inclined members are used to provide lateral support to the unsafe structure.

Such inclined members are known as the rakers or the inclined shores.

The raking Shoring mainly consists of the following components:

1. Rakers or inclined member

2. Wallplate

3. Needles

4. Cleats

5. Bracing

6. Soleplate

Usually, wall plates of sizes 23cm * 5 cm to 23cm * 76cm are used. These wall plates are fixed or secured to the walls of the structures utilizing the needles.

The 10cm * 76cm needles are commonly used for this purpose. The needles penetrate the walls up to a depth of about 10cm.

The wooden cleats are further used to provide additional strength to the needles.

Then, the top ends of the inclined shores are rested against the needles.

The sole pieces are bedded at the base of the rakers in an inclined position in the ground to support the rakers.

The rakers are fixed to such sole pieces utilizing the cleats and dogs.

In case the ground consists of soft soil layers, then the area of the sole pieces is duly increased to distribute the pressure over a larger area.

When multiple rakers are required, the rakers are held together employing the hoop iron or braces. Such braces are about 25 cm thick and 15cm wide.

The critical points that must be considered during the raking Shoring can be listed as follows:

1. The rakers are positioned to be inclined at an angle of 45 degrees to the ground as far as possible. However, the inclination angle may vary from 45 degrees to 75 degrees.

2. The rakers must be adequately braced at regular intervals.

3. In the case of tall buildings, rider rakers may be used to reduce the length of the rakers.

4. The suitable size of the rakers must be decided based on the thrust expected to be imposed by the wall.

5. It must be noted that the centerline of the wall and the raker meet at the floor level.

6. The spacing of the rakers may vary from 3 to 4.5 m to cover the longer length of the bar.

7. The sole plates of a suitable size must be used and must be properly embedded into the ground.

8. The use of wedges on the sole plate must be prohibited. This is because it increases the possibility of unnecessary vibrations to occur.

The method of erection of the raking shores can be explained in brief as follows:

1. Fixing of Wall Plate:

As far as possible, the wall plate must be continuous throughout its length.

When used for a bulging wall, the wall plates must be backed up with the timber pieces to deliver continuous bearing throughout its entire length.

Before commencing the erection of the raker, the wall plate is nailed to a cleat such that the wall plate meets the head of the raker.

It must be noted that the wall plate is adequately secured to prevent it from sliding upwards.

After nailing the cleat in position, the wall plate is held firmly against the wall and the raker is fixed.

2. Fixing of the Sole Piece:

The next step includes fixing the sole piece.

The sole piece must be placed such that it can resist the thrust of the raker at an angle greater than a right angle so that when the raker is tightened up, a right angle is duly formed.

A hammer must not do the tightening up of the raker.

Then, a small rebate is cut from the foot of the raker such that a lever can be inserted for the tightening up.

Additionally, folding wedges may be inserted between the foot of the raker.

The sole piece must be built up to the required angle and then duly spiked to prevent outward movements.

On the other hand, excavation must be done towards the unsafe wall in the soft grounds to provide the necessary angle.

Alternatively, the soleplate can also be constructed by using a plank that is as wide as the wall plate.

When the bottom of the wall plate is touching the ground, it could be allowed to rest on the end of the soleplate nearest the wall, and later a cleat may be nailed into position in the right angle thus formed.

The cleats must be nailed onto the soleplate about 50mm away from the foot of the raker. This is done to ensure that space is provided for inserting the folding wedges between the raker and the cleat.

Care must be taken during the tightening and positioning of the wedges to ensure that it does not permit the wall plate to ride up the wall.

The end of the soleplate outside the raker must be secured by a stake or a spike to prevent such movement.

3. Fixing of Brace (or Strut):

Finally, the brace or the strut is fixed. This is done to prevent any movement by the foot of the wall plate and ensure that riding up of the wall plate under stress is avoided.

The strut, if required, must be dogged or spiked.

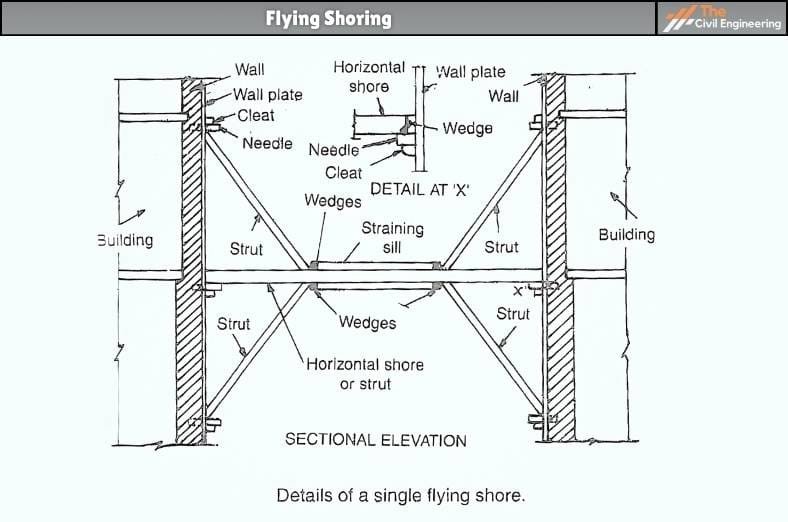

b. Flying Shoring

Flying Shoring is also commonly referred to as horizontal Shoring.

It can be defined as the Shoring, which provides temporary support to the party walls of the two buildings where the intermediate building is to be pulled down and rebuilt.

This type of Shoring includes all the arrangements for supporting the unsafe structure where the shores do not reach the ground.

Hence, the name flying Shoring has been given. The shore used for this purpose is known as the flying shore.

Fig: Flying Shoring

The major components of a flying shore can be listed as follows:

a. Wall Plates

b. Needles

c. Cleats

d. Horizontal Struts (also referred to as the horizontal shores)

e. Inclined Struts

In this type of Shoring, the wall plates are placed against the wall and duly secured. The cleats and needles system is used for supportingduly secured

The incline struts are supported by the needle at the top and the straining piece at the feet. Such a straining piece is also referred to as the straining sill. It is usually spiked to the horizontal shore.

The width of the strut and the straining piece is the same.

When the distance between the walls to be strutted apart is considerable, a horizontal shore alone cannot be efpracticalnd thus a trussed framework of members is used to serve the function of a flying sore.

The method of erection of the flying shore can be explained in brief as follows:

1. Initially, the ground is set before the erection of the flying shore such that the measurements and the angles get adequate attention.

2. Then, the cleats are duly nailed to their positions on the wall plates. The first pair is provided to provide additional support to the horizontal shore, whereas the remaining teams are provided to impart strength to the struts.

3. It must be ensured that the cleat for the horizontal beam adjacent to the surrounding wall is thick enough to allow for the wedges and an excellent overlay by the beam.

4. The horizontal beam must be given an equal cleat-bearing surface at each end.

5. The struts must th be placed at an angle not greater than 45 degrees to the horizontal beam.

The struts must be kept apart on the horizontal beam utilizing the straining pieces. The length of such straining elements must be determined according to the size of the horizontal beam.

6. The horizontal beams a, land training pieces a, are placed on the central cleat and further tightened by the folding wedges between the shore and the wall plate.

7. The struts are finally fixed between the top portion of the lower cleats and the lower struts.

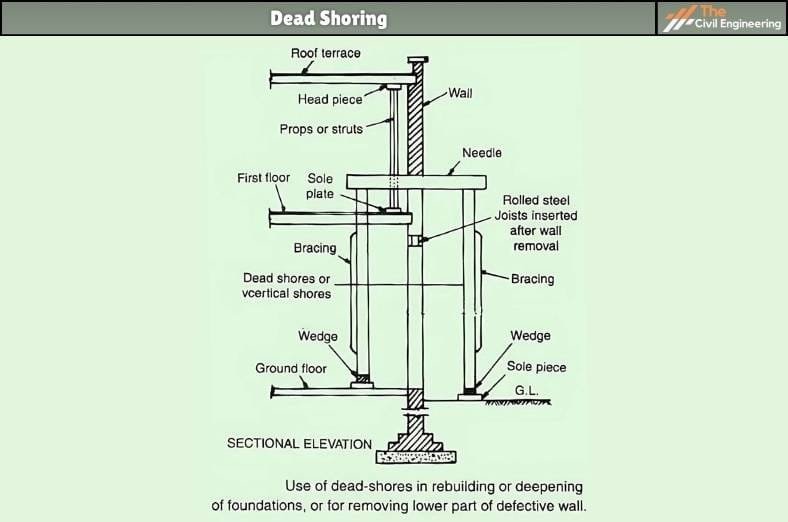

c. Dead Shoring

Dead Shoring is also called vertical Shoring.

It can be defined as the type of Shoring that is mainly used to provide support to the walls, roofs, floors, etc., particularly when the lower part of a wall has been removed to provide an additional opening in the wall or even to rebuild a defective load-bearing wall in a structure.

The shores used for such purposes are known as the dead shores.

The dead shores consist management of posts and beams. These are necessary for providing support to the weight of the overall structure and transferring the weight to the ground lying underneath the foundation.

Fig: Vertical Shorintransferring case, where the openings are to be made on an existing wall, the holes are cut in the wall at such a height that provides sufficient space for the insertion of the beam or the girder which is necessary for carrying the weight of the structure above permanently.

The distance at which such holes are formed depends upon the type of masonry structure. The standard length ranges from 1.2m to 1.8 m.

Then, the beams, referred to as the needles, are placed in the cut holes and are supported by the dead sh, ores at their ends on either,r side of the wall.

The needles may be made of steel or timber as required.

The dead shores are placed away from the wall on either side to allow space for working when the props and the needles are in position.

The props are tightened up by folding wedges provided at their bases while the junction between the supported needle is secured with the help of dogs.

The wall-cutting process may result in vibrations and shocks, and thus, for safety, sometimes the raking shores are erected before the operation.

If such a raking system is used, it must be removed only after the entire dead shore system has been removed.

Read More: Prismatic Compass

Read More: Septic Tank