1. Introduction

Stripping value test on aggregates can be defined as the test performed to determine the effects of moisture content on the adhesion of the bituminous film to the surface particles of the aggregates.

The stripping value is expressed as a percentage.

The determination of the stripping value of the road aggregates is necessary so that the applicability of both the aggregate and bitumen together can be ascertained because a particular type of aggregate may be satisfied with one binder and maybe undesirable with another binder.

2. Objectives of Stripping Value Test on Aggregates

The main objectives of the stripping value test of road aggregates can be listed as follows:

1. To determine the stripping value of aggregates to be used for the construction of the road.

2. To ascertain the suitability of the aggregates together with the bituminous binder for road construction.

3. Apparatus Required in Stripping Value Test

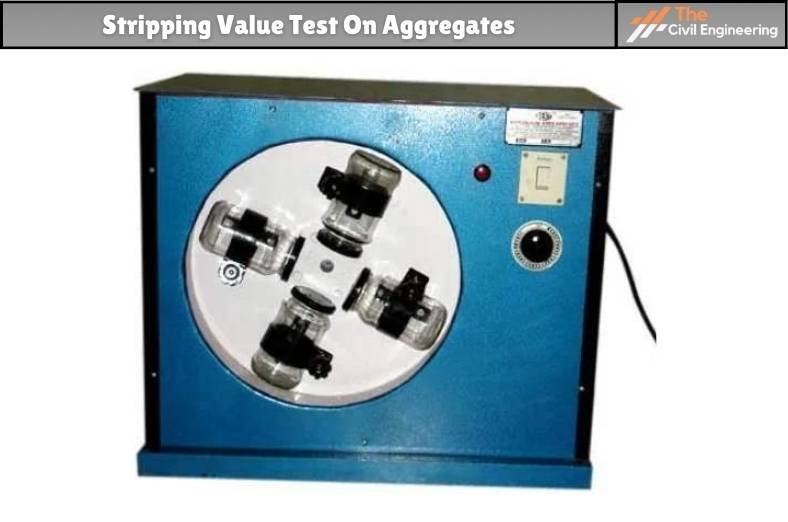

1. An oven to heat the aggregates.

2. A thermostatically controlled water bath.

3. Sieves of sizes 12.5mm and 20mm.

4. Beaker with a capacity of 500ml.

5. A mixer for mixing the aggregate sample and bituminous binder.

4. The procedure of Stripping Value Test on Aggregates

The procedure of the stripping value test involves the following series of steps:

1. A well-cleaned aggregate sample passing through a 20mm IS sieve and retained on a 12.5mm sieve is taken.

2. About 200gm of the sample is heated in the oven at a temperature of about 150 degree Celsius.

3. Then, the bituminous binder that amounts to 5 % by weight of the aggregate taken is heated up to a temperature of 160 degrees celsius.

4. The aggregate and the bituminous binder are mixed well until the aggregates are completely coated by the binder then the mixture is allowed to cool at room temperature for about 2 hours.

5. Distilled water is then added for the immersion of coated aggregates.

6. The beaker with the aggregates is then covered and kept in the water bath maintained at 40 degrees celsius for 24 hours.

7. The beaker is taken out after 24 hours and is visually examined for the extent of stripping and the stripping value is expressed as the percentage.

5. Intepretation of Result

According to the IRC standards, only those aggregates having the stripping value less than 5% are suitable for the bituminous constructions such as surface dressing, pavement construction etc.

6. Precautions Taken in Stripping Value Test

1. Distilled water must be used for the stripping value test.

2. The bituminous binder and the aggregate must be mixed thoroughly.

3. The aggregate must be properly dried before it is mixed with bitumen.

4. Apparatus must be handled with care.

| Read More: Core Cutter Method |

| Read More: In-Situ Dry Density By Sand Replacement Method |